-

Share:

Contact us

Inquiry

-

E-mail:yuxiatugong@163.comWhatsApp:3236396607

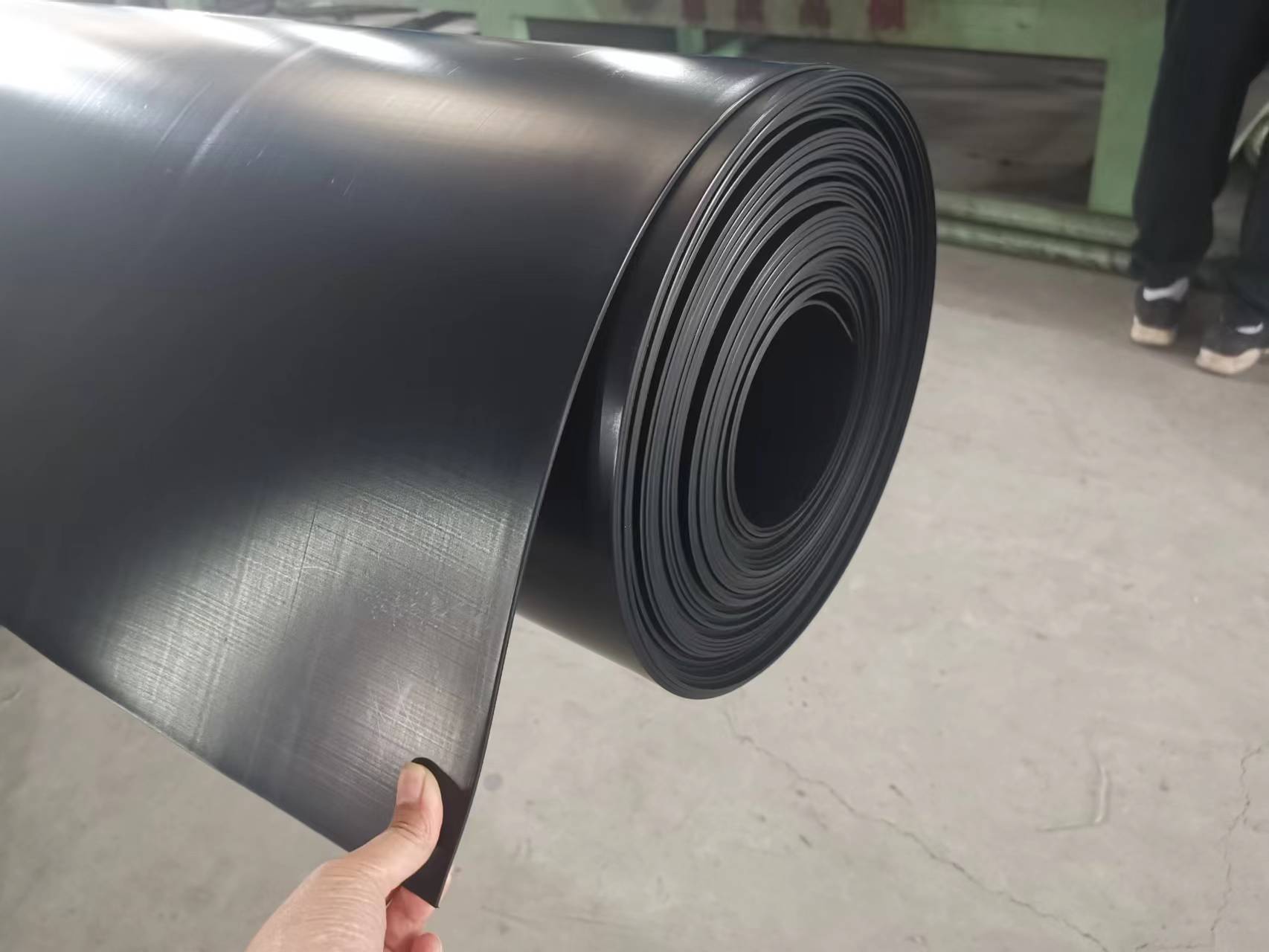

Durable, impermeable, UV-resistant, chemical-proof geomembrane

Comprehensive Geomembrane Product White Paper

Executive Summary

This white paper also highlights the importance of HDPE Geomembrane Liner, the versatility of Flexible Geomembrane Sheet, and the dependable protection offered by Waterproof Geomembrane Material in modern engineering applications.

Geomembranes are impermeable polymeric barriers that have transformed modern civil and environmental engineering.

They deliver reliable containment in applications ranging from municipal solid waste landfills and mining heap leach pads to

reservoirs, canals, aquaculture ponds, and tunnel waterproofing systems. Their success stems from a combination of

exceptionally low permeability, robust mechanical strength, strong chemical resistance, and long‑term durability under

outdoor exposure. This white paper offers a deep, practitioner‑oriented review of geomembrane technology: materials and

formulations, performance properties and test methods, manufacturing routes, system design, installation procedures,

quality assurance and control (QA/QC), maintenance, risk management, and future innovations. It is meant to help owners,

designers, contractors, and operators make technically sound and economically efficient decisions across the full lifecycle

of a geomembrane system. We emphasize practical selection criteria, field‑proven details, troubleshooting guidance, and

cost‑of‑ownership thinking so readers can translate materials science into project performance and regulatory compliance.

1. Fundamentals: What Is a Geomembrane?

A geomembrane is a continuous polymer sheet or composite barrier used to control the movement of liquids, vapors, or

solutes through soil and structural systems. In geotechnical and environmental works, it functions as the primary

impermeable element of a lining system. While compacted clay liners and asphaltic layers have long been used to reduce

permeability, geomembranes achieve orders‑of‑magnitude lower hydraulic conductivity with thinner sections, faster

installation, and more predictable performance. Typical base resins include high‑density polyethylene (HDPE), linear

low‑density polyethylene (LLDPE), low‑density polyethylene (LDPE), polyvinyl chloride (PVC), ethylene‑vinyl acetate

(EVA), and ethylene copolymer bitumen (ECB). Additive packages—carbon black for UV shielding, antioxidants to inhibit

thermal oxidation, processing aids, and sometimes fire retardants—stabilize the polymer so the liner resists cracking,

brittleness, and environmental stress over decades. Geomembranes can be smooth or textured; they can be single‑layer or

co‑extruded; and they are frequently combined with other geosynthetics such as geotextiles, geonets, and geocomposites to

create systems that separate, filter, drain, protect, and reinforce in addition to sealing. The combination of barrier

function and system integration explains why geomembranes have become foundational to modern containment design.

2. Material Families and Formulations

Within material families, the HDPE Geomembrane Liner is the industry benchmark for strength and chemical resistance. The Flexible Geomembrane Sheet provides adaptability for challenging subgrades and settlement, while Waterproof Geomembrane Material delivers robust impermeability in high‑risk environments.

HDPE Geomembrane — The industry workhorse. HDPE exhibits high tensile strength, modulus, and chemical resistance,

especially against hydrocarbons, acids, and alkalis. It offers very low permeability and excellent stress‑crack growth

resistance when properly formulated. Typical thicknesses range from 0.75 mm to 3.0 mm, with 1.5–2.0 mm common for

landfills and mining. Carbon black loading around 2–3% provides long‑term UV protection. The trade‑off is lower

conformability than LLDPE, which makes subgrade preparation and detailing critical at corners and penetrations.

LLDPE Geomembrane — Favored for its flexibility and high elongation at break, LLDPE conforms to irregular subgrades and

accommodates differential settlement better than HDPE. It is often selected for ponds, canals, floating covers, and

wastewater lagoons where strain accommodation and wrinkle management matter. Chemical resistance is strong but generally

slightly lower than HDPE; selection should consider the specific exposure environment.

LDPE Geomembrane — Offers good flexibility and processability with lower modulus and strength. It is used in light‑duty

containment, temporary works, and small agricultural or decorative water features where extreme chemical resistance is not

required. In structural or aggressive chemical environments, other resins are normally preferred.

PVC Geomembrane — Plasticized PVC membranes are notably flexible and easy to detail around complex penetrations. They are

common in tunnels, subgrade waterproofing, and some tank‑lining applications. As plasticizer migration can affect long‑term

mechanical properties, reputable formulations and correct cover systems are essential for durable performance.

EVA Geomembrane — EVA improves low‑temperature flexibility and stress‑crack resistance. It is used in subway and tunnel

waterproofing, as well as on projects where thermal cycling is severe. Adhesion to concrete with compatible primers is a

design advantage in some systems.

ECB Geomembrane — A composite of ethylene copolymer and bitumen, ECB membranes combine the self‑healing tendencies of

bitumen with the mechanical strength of a polyolefin. They can be hot‑bonded to form continuous waterproofing layers in

tunnels and underground structures.

Textured and Structured Surfaces — Texturing (single‑ or double‑sided) increases interface friction on slopes and against

geotextiles or soils, improving stability. Structured liners may use studs or embossed patterns to tune contact behavior.

Surface engineering is as important as resin selection when designing for steep slopes and seismic loading.

3. Performance Properties and Why They Matter

Impermeability — The defining attribute of a geomembrane is its extremely low hydraulic conductivity. In practice,

impermeability is achieved not only by resin selection and film integrity, but also by the quality of seams, penetrations,

and terminations. An outstanding sheet installed with poor welding, inadequate anchorage, or improperly detailed

penetrations will still leak. Thus, product performance and system execution are inseparable.

Mechanical Strength — Tensile strength and elongation determine a liner’s ability to carry strain without tearing. Puncture

and tear resistance defend against damage from subgrade irregularities, gravel placement, and operational loads. Design

should integrate protective geotextiles and granular cushions where impact or point loading is expected.

Stress‑Crack and Fatigue Resistance — Polyolefin liners can fail by slow crack growth under sustained stress and chemical

attack. Modern resins and antioxidant packages dramatically delay this process, but temperature, notch geometry, and

chemical environment remain decisive. Textbook values mean little if detailing concentrates stress; rounded corners,

appropriate backing, and generous radii are cheap insurance.

Thermal Behavior — Coefficients of thermal expansion are large for polymers. Diurnal cycles cause expansion and contraction,

which can mobilize wrinkles or concentrate strain at anchors and penetrations. Designs should incorporate sufficient slack,

construct in early morning when possible, and plan ballast or cover placement to immobilize the sheet within acceptable

strain envelopes.

UV and Weathering Resistance — Uncovered liners are exposed to solar radiation, oxygen, and moisture. Carbon black is a

highly effective UV stabilizer for HDPE/LLDPE, while light‑colored reflective surfaces can reduce heat buildup. Where

long‑term exposure is unavoidable, higher stabilizer levels and periodic inspection are essential.

Chemical Compatibility — From acidic leachate to saline brines and hydrocarbon mixtures, the chemical resistance matrix

must be matched to the project. HDPE is strong across many categories; PVC and EVA may be preferred where flexibility and

bonding are essential; specialty formulations address fuels and solvents. Always evaluate with representative fluids and

temperatures rather than assuming generic resistance.

Service Life — With appropriate formulation, detailing, and cover, service life of decades is achievable. Lifetime models

consider antioxidant depletion, thermal oxidation, stress‑crack growth, and UV weathering. Conservative design margins and

QA/QC habits are the best predictors of actual longevity.

4. Manufacturing Routes and Quality Controls

Flat‑Die and Blown‑Film Extrusion — Most polyolefin geomembranes are produced by extruding molten resin through a die and

quenching into sheet. Blown‑film routes create tubular films that are slit and flattened; flat‑die routes produce wide

sheets directly. Co‑extrusion allows multiple layers—for example, a textured outer skin for friction and a smooth core for

barrier performance. Online measurements (thickness gauges, optical inspection) monitor uniformity in real time.

Calendering and Coating — PVC and ECB membranes are often calendered to precise thickness or coated onto carrier fabrics.

Plasticizer selection, gelation temperature, and calendering pressure determine mechanical and aging behavior.

Texturing and Structuring — Textures are imparted by rollers, air knives, or embossing during or after extrusion. Double‑

sided texturing improves friction on both interfaces of a slope; single‑sided may be chosen where one interface should

remain smooth for testing or fusion.

Factory QA — Resin certification, melt flow index tracking, carbon black dispersion grading, oxidative induction time (OIT)

testing, and plaque mechanical testing are standard. Each roll is tagged for traceability. A robust factory quality plan

reduces variability that field crews would otherwise have to absorb.

5. Friction, Interface Behavior, and Stability on Slopes

Slope stability is the governing limit state for many lining systems. The shear strength at the interfaces—geomembrane to

soil, geomembrane to geotextile, and geotextile to soil—controls the factor of safety against sliding. Laboratory direct

shear tests at normal stresses representative of field conditions should be conducted for the exact materials proposed.

Textured membranes typically increase peak and residual friction angles; however, they may modestly reduce tensile

properties versus smooth sheet. Designers often specify different textures on the top and bottom faces to tune performance

for each interface. Construction sequencing also influences stability: placing cover soils in thin lifts, avoiding drop

heights that could puncture the liner, and using low‑ground‑pressure equipment protect both friction and integrity.

Anchorage at the crest, sufficient toe berms, and buttressing in critical areas are standard risk controls.

6. System Integration with Other Geosyntheticss

Geomembranes rarely act alone. A complete lining system typically includes a prepared subgrade; a cushion geotextile to

absorb point loads and protect against puncture; a composite drainage layer formed by a geonet bonded to geotextiles to

collect and convey fluids; and a leak detection layer below or between membranes in double‑lined systems. In leach pads and

landfills, a primary and secondary geomembrane may be separated by a geonet or geocomposite to allow active leak detection

and drainage. On canals and reservoirs, the geomembrane may be covered by concrete slabs, shotcrete, riprap, or soil to

protect against mechanical damage, UV, and vandalism. Each interface should be designed for filtration and drainage as well

as barrier function so the system works as an integrated whole. The best projects treat the liner as a component in a

hydraulic‑geotechnical network rather than a standalone sheet.

7. Design and Selection Criteria

Project owners and engineers should translate functional requirements into measurable criteria:

• Hydraulic barrier performance: target seepage rate, head conditions, and allowable leakage.

• Chemical exposure: pH range, salts, hydrocarbons, process solutions, temperature.

• Mechanical demands: slope angles, subgrade roughness, traffic, ballast, cover thickness.

• Construction environment: ambient temperatures, wind, access, panel sizes and handling limits.

• Regulatory requirements: liner thickness, double‑lining mandates, leak detection sensitivity.

• Inspection and maintainability: access for testing, survey, repairs, and long‑term monitoring.

For example, a landfill side slope may require a double‑textured 2.0 mm HDPE with high OIT and robust stress‑crack

resistance; a decorative pond may perform well with 1.0 mm LLDPE; a tunnel waterproofing system might prefer a PVC or EVA

membrane bonded to protection boards and drainage composites. Good selection avoids over‑specification that wastes budget

and under‑specification that risks containment failure.

8. Standards, Test Methods, and Documentation

Commonly referenced material and seam standards include: index tensile tests, wide‑width tensile tests for geosynthetics,

puncture and tear indices, OIT and high‑pressure OIT, carbon black content and dispersion, density and melt flow index,

and notched constant tensile load (NCTL) for stress‑crack behavior. Seam testing uses peel and shear strength via coupons

cut from trial seams and production welds, along with non‑destructive methods (air channel testing for dual‑track fusion,

vacuum box testing for extrusion seams, and spark testing for conductive layers). Documentation should link roll numbers to

panel layouts, weld logs, test results, and repair records so any future observation can be traced back to manufacturing and

installation histories. A culture of paperwork discipline is not bureaucratic overhead—it is the memory of the liner system.

9. Applications and Mini Case Studies

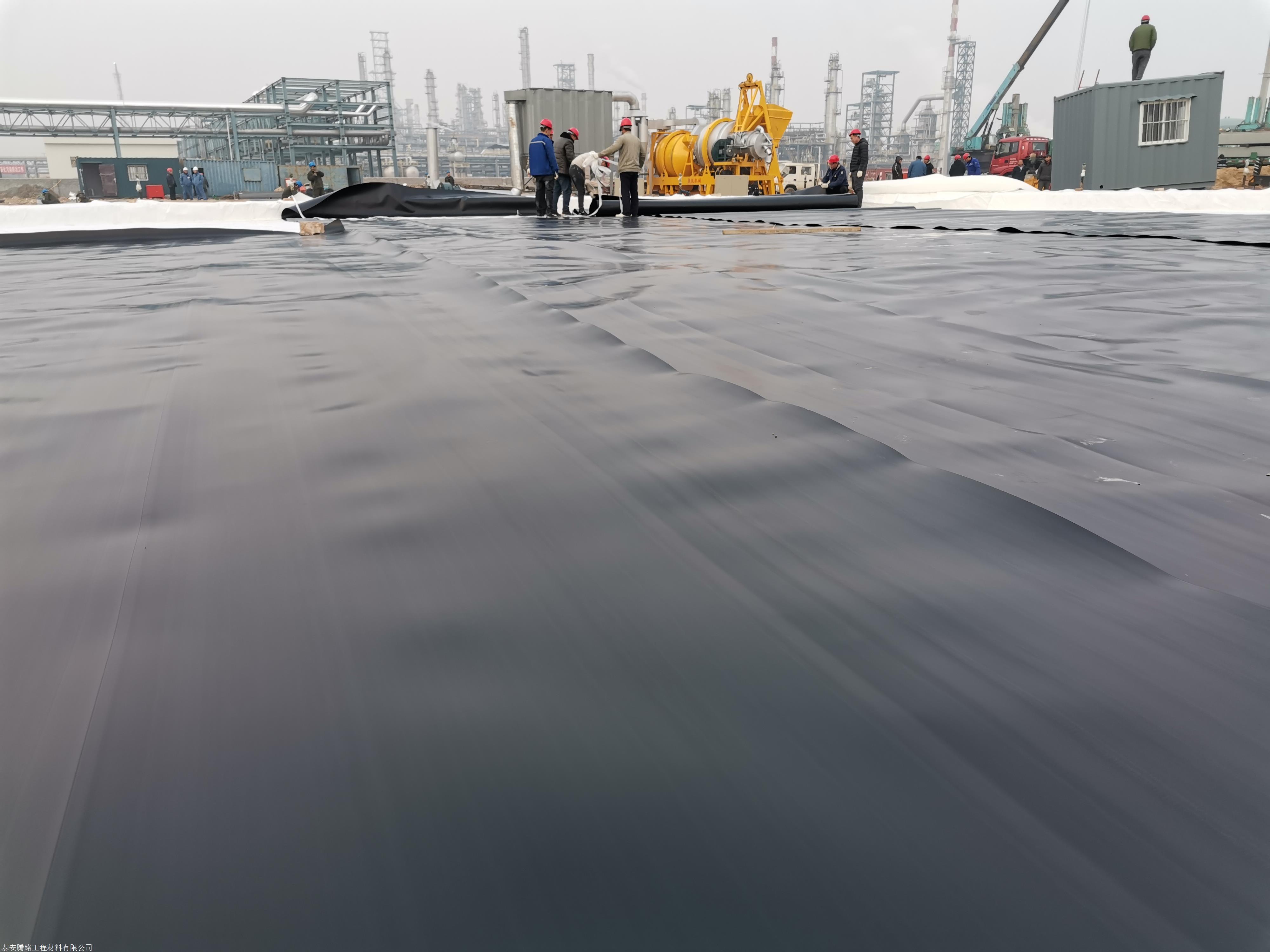

In each sector—from landfills and mining to aquaculture and tunnel waterproofing—the integration of HDPE Geomembrane Liner, Flexible Geomembrane Sheet, and Waterproof Geomembrane Material ensures the highest levels of safety, environmental compliance, and cost efficiency.

Landfills — Double‑lined systems with leak detection have become standard for municipal solid waste. A typical section

includes a primary textured HDPE geomembrane over a composite drainage layer and a secondary geomembrane above a compacted

clay or geosynthetic clay liner. Case histories show dramatic reductions in leachate escape and regulatory compliance risks

when QA/QC is rigorous and slopes are detailed with compatible friction angles at each interface.

Mining — Heap leach facilities require tens to hundreds of hectares of lining. The liner must tolerate cyclic loading from

stacked ore, aggressive process solutions (e.g., cyanide), high temperatures, and settlement. Successful projects pair

high‑quality HDPE with sacrificial protection geotextiles, careful subgrade preparation, and disciplined panel sequencing to

manage thermal movement.

Water Resources — Reservoirs, irrigation canals, and stormwater basins use geomembranes to curb seepage losses and protect

adjacent foundations from softening. A reservoir retrofit in a semi‑arid region, for example, replaced a cracked clay liner

with 1.5 mm textured HDPE topped by soil and riprap; measured losses fell by more than half, enabling a smaller pumping

budget and greater drought resilience.

Aquaculture — Fish and shrimp farms benefit from cleanable, non‑toxic LLDPE or HDPE liners that maintain water quality and

biosecurity. Operators report more predictable pH and oxygen profiles, faster pond turnaround between crops, and simplified

sludge removal compared with unlined earth ponds.

Transportation and Tunnels — PVC and EVA membranes, often yellow or white for inspection contrast, provide continuous

waterproofing behind shotcrete or cast‑in‑place linings. Drainage composites control hydrostatic pressure so water is routed

to collection points rather than through cracks and joints.

Industrial and Energy — Secondary containment for chemical tanks, brine ponds at power plants, and ash basins at thermal

stations rely on chemical‑compatible liners with robust seams and penetrations detailed to withstand thermal cycles.

10. Installation: Tools, Crew, and Step‑by‑Step Field Procedures

Successful installation transforms rolls into a continuous barrier without introducing defects. Core practices include:

Planning and Logistics — Review drawings and panel layout; plan roll lengths, lift points, and crane or spreader bar

requirements; schedule work during periods of low wind and moderate temperature to control wrinkles and seam quality. Stage

rolls on pallets, protect them from dirt and UV before deployment, and verify roll tags for traceability.

Subgrade Preparation — Grade, compact, and proof‑roll the subgrade; remove sharp stones and debris; fill ruts; round

corners and steps. Many failures originate from hurried or inconsistent surface prep. Where needed, place a nonwoven

geotextile cushion.

Panel Deployment — Unroll down‑slope to reduce bridging. Align sheets with overlap allowances (typically 100–150 mm for

dual‑track fusion seams; more for extrusion seams). Temporarily ballast edges with sandbags to prevent wind uplift.

Welding and Seaming — Use dual‑track hot‑wedge fusion for primary seams on polyolefin liners; set temperature, speed, and

pressure based on trial seams and ambient conditions. Extrusion welds close T‑seams, patches, and details. Maintain clean,

dry surfaces; use rounded cuts to avoid stress risers. Keep a running log of machine settings, operator, time, and seam IDs.

Non‑Destructive Testing — Air‑pressure test dual‑track seams (inflate the channel, hold pressure, and verify no decay).

Vacuum box test extrusion seams with soap solution; inspect for bubbles that indicate leaks. Conduct spark testing where

conductive backings are present. Mark defects for immediate repair.

Destructive Testing — Cut seam coupons at prescribed frequencies; test peel and shear strength against project criteria.

Patch coupon locations per procedure. Laboratory confirmation on retained samples validates field measurements.

Details and Penetrations — Pipes, sumps, concrete plinths, and appurtenances require precision. Use prefabricated boots or

field‑fabricated collars with extrusion welds. Provide stress‑relief via generous radii and reinforcement pads. Seal

terminations in anchor trenches with compacted backfill or compatible concrete.

Cover Placement — As soon as practical, place protective soil or ballast to immobilize the liner and shield it from UV and

wind. Use low‑ground‑pressure equipment, limit drop heights, and avoid sharp‑edged material. Survey and as‑built

documentation close out the installation phase.

11. QA/QC Program: From Factory to Field

A robust QA/QC plan ties together procurement, manufacturing, installation, and verification. Factory quality assurance

documents resin sources, additive packages, and roll‑by‑roll test results. Field quality control verifies subgrade

acceptance, tracks panel layouts, records weather and equipment settings, and tests seams non‑destructively and

destructively at required frequencies. Third‑party quality assurance provides independent oversight, audits records, and

witnesses critical tests. Digital photo logs, GPS‑referenced seam maps, and cloud‑based documentation systems have improved

traceability. Owners who invest in QA/QC experience fewer leaks, faster regulatory approvals, and lower lifecycle costs.

12. Maintenance, Monitoring, and Repair

Even the best liner systems benefit from planned observation. After commissioning, periodic visual surveys look for animal

damage, wind uplift, erosion of cover soils, settlement cracks, or stress concentrations near penetrations and anchors.

Monitoring wells and leak‑detection systems provide early warning of containment loss. Repairs follow a clean, dry, and

controlled protocol: trim damaged areas to sound material with rounded corners; abrade and wipe surfaces; apply a matching

patch; and extrusion weld with proper bead geometry. Post‑repair vacuum box testing confirms integrity. Where liners remain

exposed, schedule inspections after major weather events and at seasonal temperature extremes to catch issues early.

13. Health, Safety, and Environmental (HSE) Considerations

Liner projects integrate many moving parts—cranes, wind, heat, slippery surfaces—so HSE discipline is non‑negotiable.

Crews should use cut‑resistant gloves, eye protection, and harnesses on steep slopes. Hot‑wedge and extrusion equipment

requires guarding and lockout procedures. Solvent use should be minimized; where used, ensure ventilation and compatible

cleaners. Fire prevention protocols apply around fuels and hot work. Environmentally, geomembranes are inert and help

protect soil and groundwater by design; construction waste should be minimized and responsibly recycled where possible.

Site erosion and sediment controls keep disturbed soils out of waterways during installation.

14. Cost, Risk, and Value Engineering

Upfront material price is visible, but total cost of ownership is driven by risk and performance. A thinner, marginally

cheaper liner that wrinkles excessively, punctures under cover placement, or suffers poor seams can cost far more in rework,

delays, and leakage consequences. Value engineering weighs resin type, thickness, texture, cushion layers, and drainage

composites as an integrated system. Often, spending modestly more on texture for slope stability, on geotextile protection

for puncture control, or on enhanced QA/QC pays back in reduced risk. Owners should budget for independent CQA and seam

testing, as the ROI is excellent compared with the cost of a leak investigation after operation begins.

15. Common Pitfalls and Troubleshooting

Frequent issues include: inadequate subgrade preparation (sharp stones puncture liners); welding in high winds or with wet,

dirty surfaces (weak seams); insufficient slack in panels (thermal contraction tears seams or induces stress); mixing

incompatible materials (PVC with incompatible adhesives or HDPE with non‑approved sealants); ignoring interface friction on

steep slopes (sliding during cover placement); and poor documentation (hard to defend performance to regulators). A

troubleshooting mindset asks: is this a materials issue, a detailing issue, an installation process issue, or an operations

issue? Systematic root‑cause analysis prevents repeat occurrences and improves institutional knowledge.

16. Technology Outlook and Innovation Pathways

Emerging work focuses on smarter liners and greener polymers. Conductive backings enable continuous spark testing of seams,

raising confidence in leak‑free commissioning. Multi‑functional liners integrate drainage or sensor networks that detect

moisture or strain in real time. Research into recycled‑content polyolefins and bio‑based additives aims to reduce carbon

footprint without sacrificing durability. Surface engineering continues to evolve, with micro‑textures that tune friction

without eroding tensile properties. Digital twins of heap leach facilities and landfills combine geosynthetic material

models with operational data so managers can forecast risks and optimize cover placement, pumping, and reclamation plans.

17. Glossary of Key Terms

• Antioxidant: Additive that delays thermal oxidation of polymers, extending service life.

• Anchor Trench: Excavated trench at slope crests or perimeters where a liner is buried for mechanical fixation.

• Carbon Black: UV‑absorbing additive dispersed in polyolefins for outdoor durability.

• CQA/CQC: Construction Quality Assurance/Construction Quality Control; independent assurance vs. contractor’s control.

• Dual‑Track Fusion: Hot‑wedge welding that creates two parallel fusion bonds with an air channel for pressure testing.

• Geotextile: Permeable fabric used for filtration, separation, reinforcement, or cushioning.

• Geonet/Geocomposite: Net‑like core that conveys fluids, often bonded to geotextiles for filtration and protection.

• HDPE/LLDPE/LDPE: Polyethylene families with differing density, crystallinity, flexibility, and strength.

• OIT (Oxidative Induction Time): Laboratory measure of antioxidant reserve in polyolefins.

• Stress‑Crack: Slow crack growth phenomenon in polyolefins under sustained stress and chemical environment.

• Textured Liner: Geomembrane with engineered surface roughness to increase interface friction.

18. Appendix: Example Specifications and Submittal Checklist

Example HDPE Specification (excerpt): Resin shall be prime, meeting melt flow index limits suitable for sheet extrusion;

carbon black content 2.0–3.0% with dispersion grades ≤3 per standard; nominal thickness 1.5 mm; density 0.94–0.97 g/cm³;

OIT ≥ 100 minutes at specified temperature; tensile properties meeting wide‑width criteria; NCTL stress‑crack time meeting

project minimums. Rolls shall be marked with manufacturer, lot, roll number, production date, and QC results summary.

Submittal Checklist: product data sheets; resin certification; carbon black dispersion results; thickness profile reports;

OIT values; wide‑width tensile data; index puncture and tear values; recommended welding parameters; sample seam peel and

shear data from trial welds; proposed panel layout drawings; QA/QC plan; installation method statements; HSE plan; and

training records for welding operators. Thorough submittals accelerate approvals and reduce site queries.

- Previous page: None

- Next page: Flexible, waterproof, eco-friendly, aquaculture-safe fish pond geomembrane

Phone

Phone