-

Español

Español

-

Portugues

Portugues

-

Pусский

Pусский

-

Français

Français

-

Deutsch

Deutsch

-

日本語

日本語

-

한국어

한국어

-

العربية

العربية

-

Italiano

Italiano

-

Nederlands

Nederlands

-

Ελληνικά

Ελληνικά

-

Svenska

Svenska

-

Polski

Polski

-

ไทย

ไทย

-

Türk dili

Türk dili

-

हिन्दी

हिन्दी

-

Indonesia

Indonesia

-

Melayu

Melayu

-

Tiếng Việt

Tiếng Việt

-

中文

中文

-

dansk

dansk

-

Magyar

Magyar

-

қазақ

қазақ

-

বাংলা

বাংলা

-

עִברִית

עִברִית

-

čeština

čeština

-

Soomaali

Soomaali

-

မြန်မာ

မြန်မာ

-

فارسی

فارسی

-

українська

українська

-

norsk

norsk

-

Gaeilge

Gaeilge

-

беларускі

беларускі

-

Română

Română

-

ພາສາລາວ

ພາສາລາວ

-

Filipino

Filipino

-

lietuvių

lietuvių

-

Cymraeg

Cymraeg

-

македонски

македонски

-

Suomalainen

Suomalainen

-

slovenský

slovenský

-

o'zbek

o'zbek

-

اردو

اردو

-

հայերեն

հայերեն

-

Igbo

Igbo

-

български

български

-

سنڌي

سنڌي

-

Shona

Shona

-

සිංහල

සිංහල

-

Hrvatski

Hrvatski

-

íslenskur

íslenskur

-

galego

galego

-

català

català

-

Zulu South Africa

Zulu South Africa

-

Afrikaans isiXhosa

Afrikaans isiXhosa

-

ಕನ್ನಡ

ಕನ್ನಡ

-

lëtzebuergesch

lëtzebuergesch

-

Indonésia Sunda

Indonésia Sunda

-

basa jawa

basa jawa

-

ગુજરાતી

ગુજરાતી

-

Кыргызча

Кыргызча

-

тоҷикӣ

тоҷикӣ

-

Србија

Србија

-

Twi

Twi

-

Hawaii

Hawaii

-

Cebu

Cebu

-

नेपाल

नेपाल

-

euskara

euskara

-

Kurdî

Kurdî

-

frissi

frissi

-

יידיש

יידיש

-

latvija

latvija

-

slovenija

slovenija

-

kiswahili

kiswahili

-

ਪੰਜਾਬ

ਪੰਜਾਬ

-

پښتو

پښتو

-

საქართველოს

საქართველოს

-

hua moni

hua moni

-

bosna

bosna

-

తెలుగు

తెలుగు

-

தமிழ்

தமிழ்

-

Kreyòl ayisyen

Kreyòl ayisyen

-

Eesti

Eesti

-

Corsica

Corsica

-

Yoruba

Yoruba

-

Gàidhlig na h-Alba

Gàidhlig na h-Alba

-

Samoa

Samoa

-

Монгол

Монгол

-

Hausa

Hausa

-

Azərbaycan

Azərbaycan

-

አማራ

አማራ

-

Shqipëria

Shqipëria

-

Malagasy

Malagasy

-

मराठी

मराठी

-

മലയാളം

മലയാളം

-

Malta

Malta

-

ខ្មែរ

ខ្មែរ

-

Chicheva

Chicheva

-

中文(繁体)

中文(繁体)

-

ଓଡିଆ

ଓଡିଆ

-

Setswana

Setswana

-

Afrikaans

Afrikaans

-

Aymara

Aymara

-

Башҡорт

Башҡорт

-

Türkmenler

Türkmenler

-

ትግሪኛ

ትግሪኛ

-

Afaan Oromoo

Afaan Oromoo

-

অসমীয়া

অসমীয়া

-

Kinyarwanda

Kinyarwanda

-

Ilocano

Ilocano

-

Wolof

Wolof

-

अवधी

अवधी

-

Oluganda

Oluganda

-

Bikol

Bikol

-

Fulɓe

Fulɓe

-

Kikongo

Kikongo

-

Sango

Sango

-

ދިވެހި

ދިވެހި

-

Lingala

Lingala

-

मैथिली

मैथिली

-

Tsonga

Tsonga

-

ꯃꯦꯏ ꯊꯥꯏ꯫

ꯃꯦꯏ ꯊꯥꯏ꯫

-

brezhoneg

brezhoneg

-

Furlan

Furlan

-

नेवा

नेवा

-

རྫོང་ཁ

རྫོང་ཁ

-

Santali

Santali

-

Аҧсуа

Аҧсуа

-

Нохчийн

Нохчийн

-

Чӑваш

Чӑваш

-

Татар

Татар

-

Batak Karo

Batak Karo

-

دری

دری

-

Diura

Diura

-

Fengyu

Fengyu

-

Eʋegbe

Eʋegbe

-

Iban

Iban

-

Fiji

Fiji

-

Tonga

Tonga

-

Inuktitut

Inuktitut

-

Nahuatl

Nahuatl

-

maaya yucatec

maaya yucatec

-

Runasimi

Runasimi

-

guarani

guarani

-

Qafar

Qafar

-

Acholi

Acholi

-

Dinka

Dinka

-

Luo

Luo

-

Lundi

Lundi

-

isiNdebele

isiNdebele

-

Tshivenḓa

Tshivenḓa

-

Sesotho sa Leboa

Sesotho sa Leboa

-

Sesotho sa Borwa

Sesotho sa Borwa

-

Ndumbe

Ndumbe

-

Papuan Pidgin

Papuan Pidgin

-

Rromani ćhib

Rromani ćhib

-

Thok Nath

Thok Nath

yuxiatugong@163.com

+86 18353494641

-

Español

Español

-

Portugues

Portugues

-

Pусский

Pусский

-

Français

Français

-

Deutsch

Deutsch

-

日本語

日本語

-

한국어

한국어

-

العربية

العربية

-

Italiano

Italiano

-

Nederlands

Nederlands

-

Ελληνικά

Ελληνικά

-

Svenska

Svenska

-

Polski

Polski

-

ไทย

ไทย

-

Türk dili

Türk dili

-

हिन्दी

हिन्दी

-

Indonesia

Indonesia

-

Melayu

Melayu

-

Tiếng Việt

Tiếng Việt

-

中文

中文

-

dansk

dansk

-

Magyar

Magyar

-

қазақ

қазақ

-

বাংলা

বাংলা

-

עִברִית

עִברִית

-

čeština

čeština

-

Soomaali

Soomaali

-

မြန်မာ

မြန်မာ

-

فارسی

فارسی

-

українська

українська

-

norsk

norsk

-

Gaeilge

Gaeilge

-

беларускі

беларускі

-

Română

Română

-

ພາສາລາວ

ພາສາລາວ

-

Filipino

Filipino

-

lietuvių

lietuvių

-

Cymraeg

Cymraeg

-

македонски

македонски

-

Suomalainen

Suomalainen

-

slovenský

slovenský

-

o'zbek

o'zbek

-

اردو

اردو

-

հայերեն

հայերեն

-

Igbo

Igbo

-

български

български

-

سنڌي

سنڌي

-

Shona

Shona

-

සිංහල

සිංහල

-

Hrvatski

Hrvatski

-

íslenskur

íslenskur

-

galego

galego

-

català

català

-

Zulu South Africa

Zulu South Africa

-

Afrikaans isiXhosa

Afrikaans isiXhosa

-

ಕನ್ನಡ

ಕನ್ನಡ

-

lëtzebuergesch

lëtzebuergesch

-

Indonésia Sunda

Indonésia Sunda

-

basa jawa

basa jawa

-

ગુજરાતી

ગુજરાતી

-

Кыргызча

Кыргызча

-

тоҷикӣ

тоҷикӣ

-

Србија

Србија

-

Twi

Twi

-

Hawaii

Hawaii

-

Cebu

Cebu

-

नेपाल

नेपाल

-

euskara

euskara

-

Kurdî

Kurdî

-

frissi

frissi

-

יידיש

יידיש

-

latvija

latvija

-

slovenija

slovenija

-

kiswahili

kiswahili

-

ਪੰਜਾਬ

ਪੰਜਾਬ

-

پښتو

پښتو

-

საქართველოს

საქართველოს

-

hua moni

hua moni

-

bosna

bosna

-

తెలుగు

తెలుగు

-

தமிழ்

தமிழ்

-

Kreyòl ayisyen

Kreyòl ayisyen

-

Eesti

Eesti

-

Corsica

Corsica

-

Yoruba

Yoruba

-

Gàidhlig na h-Alba

Gàidhlig na h-Alba

-

Samoa

Samoa

-

Монгол

Монгол

-

Hausa

Hausa

-

Azərbaycan

Azərbaycan

-

አማራ

አማራ

-

Shqipëria

Shqipëria

-

Malagasy

Malagasy

-

मराठी

मराठी

-

മലയാളം

മലയാളം

-

Malta

Malta

-

ខ្មែរ

ខ្មែរ

-

Chicheva

Chicheva

-

中文(繁体)

中文(繁体)

-

ଓଡିଆ

ଓଡିଆ

-

Setswana

Setswana

-

Afrikaans

Afrikaans

-

Aymara

Aymara

-

Башҡорт

Башҡорт

-

Türkmenler

Türkmenler

-

ትግሪኛ

ትግሪኛ

-

Afaan Oromoo

Afaan Oromoo

-

অসমীয়া

অসমীয়া

-

Kinyarwanda

Kinyarwanda

-

Ilocano

Ilocano

-

Wolof

Wolof

-

अवधी

अवधी

-

Oluganda

Oluganda

-

Bikol

Bikol

-

Fulɓe

Fulɓe

-

Kikongo

Kikongo

-

Sango

Sango

-

ދިވެހި

ދިވެހި

-

Lingala

Lingala

-

मैथिली

मैथिली

-

Tsonga

Tsonga

-

ꯃꯦꯏ ꯊꯥꯏ꯫

ꯃꯦꯏ ꯊꯥꯏ꯫

-

brezhoneg

brezhoneg

-

Furlan

Furlan

-

नेवा

नेवा

-

རྫོང་ཁ

རྫོང་ཁ

-

Santali

Santali

-

Аҧсуа

Аҧсуа

-

Нохчийн

Нохчийн

-

Чӑваш

Чӑваш

-

Татар

Татар

-

Batak Karo

Batak Karo

-

دری

دری

-

Diura

Diura

-

Fengyu

Fengyu

-

Eʋegbe

Eʋegbe

-

Iban

Iban

-

Fiji

Fiji

-

Tonga

Tonga

-

Inuktitut

Inuktitut

-

Nahuatl

Nahuatl

-

maaya yucatec

maaya yucatec

-

Runasimi

Runasimi

-

guarani

guarani

-

Qafar

Qafar

-

Acholi

Acholi

-

Dinka

Dinka

-

Luo

Luo

-

Lundi

Lundi

-

isiNdebele

isiNdebele

-

Tshivenḓa

Tshivenḓa

-

Sesotho sa Leboa

Sesotho sa Leboa

-

Sesotho sa Borwa

Sesotho sa Borwa

-

Ndumbe

Ndumbe

-

Papuan Pidgin

Papuan Pidgin

-

Rromani ćhib

Rromani ćhib

-

Thok Nath

Thok Nath

News Center

News Center

HOT PRODUCT

Durable Wastewater Composite Geomembrane for Sewage Treatment

2025-10-09 14:35:40

Durable Wastewater Composite Geomembrane for Sewage Treatment

Introduction

Wastewater treatment is a critical process in modern environmental management, requiring materials that can withstand harsh conditions while preventing contamination of surrounding soil and groundwater. Composite geomembranes have emerged as one of the most effective solutions for lining wastewater treatment facilities due to their exceptional durability, chemical resistance, and impermeability. This technical paper examines the properties, manufacturing processes, installation techniques, and performance characteristics of durable wastewater composite geomembranes specifically designed for sewage treatment applications.

Composition and Structure

Composite geomembranes for wastewater treatment typically consist of multiple layers engineered to provide optimal performance:

1. Polymer Layer: The primary barrier is usually made from high-density polyethylene (HDPE), linear low-density polyethylene (LLDPE), polyvinyl chloride (PVC), or ethylene propylene diene monomer (EPDM). HDPE is particularly favored for its excellent chemical resistance and durability.

2. Reinforcement Layer: Many composite geomembranes incorporate a geotextile or fabric layer to enhance tensile strength and puncture resistance. This layer also helps distribute stresses across the membrane.

3. Protective Layer: Some designs include an additional protective layer to shield against abrasion, UV radiation, or other environmental factors that could degrade performance over time.

The combination of these layers creates a material that is simultaneously flexible, strong, and impermeable—ideal characteristics for wastewater containment applications.

Key Properties for Sewage Treatment Applications

1. Chemical Resistance

Wastewater contains a complex mixture of organic compounds, acids, alkalis, and potentially hazardous chemicals. A high-quality composite geomembrane must demonstrate resistance to:

- pH extremes (typically from 1 to 14)

- Organic solvents

- Hydrocarbons

- Biological byproducts

- Disinfection chemicals (chlorine, ozone, etc.)

HDPE-based membranes generally offer the broadest chemical resistance profile, maintaining integrity even when exposed to aggressive substances commonly found in sewage.

2. Impermeability

The primary function of any geomembrane in wastewater applications is to prevent leakage. Composite geomembranes achieve extremely low permeability coefficients, typically in the range of 1×10⁻¹² to 1×10⁻¹⁴ cm/s. This effectively prevents the migration of liquids and dissolved contaminants.

3. Mechanical Strength

Sewage treatment geomembranes must withstand:

- Installation stresses

- Long-term loading from overlying materials

- Potential punctures from sharp objects

- Tensile forces during placement and service

Composite designs with reinforcement layers can achieve tensile strengths exceeding 30 kN/m while maintaining elongation properties of 300-700%.

4. Durability and Longevity

Properly formulated and installed composite geomembranes can provide service lives of 30-50 years in wastewater applications. Key durability factors include:

- UV stabilization for exposed applications

- Antioxidant packages to prevent oxidative degradation

- Resistance to environmental stress cracking

- Thermal stability for temperature variations

5. Flexibility and Conformability

The ability to conform to irregular surfaces and accommodate minor substrate movements is essential. Composite geomembranes balance flexibility with dimensional stability, allowing them to be installed on various contours without excessive stress concentrations.

Manufacturing Processes

The production of high-performance composite geomembranes involves several critical steps:

1. Polymer Compounding: Base resins are blended with additives including UV stabilizers, antioxidants, colorants, and processing aids. The formulation is carefully controlled to ensure consistent performance.

2. Extrusion: For single-layer membranes, the compounded material is extruded through a flat or circular die to form continuous sheets. Multi-layer composites may use co-extrusion or separate lamination processes.

3. Reinforcement Incorporation: Fabric or geotextile layers are either laminated to the polymer sheet or embedded during extrusion. The bonding method significantly affects the final product's performance.

4. Surface Texturing: Many wastewater geomembranes feature textured surfaces to improve interface friction with adjacent materials. This can be achieved through various methods including co-extrusion of textured layers or post-production embossing.

5. Quality Control Testing: Finished products undergo rigorous testing for thickness consistency, tensile properties, seamability, and chemical resistance before being approved for shipment.

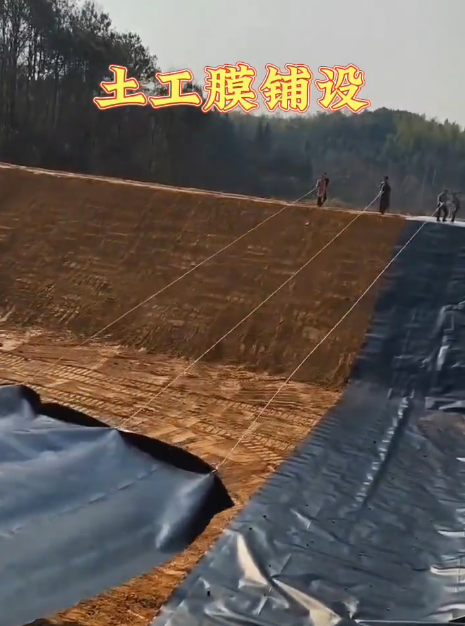

Installation Considerations

Proper installation is crucial for realizing the full performance potential of composite geomembranes in wastewater applications:

1. Subgrade Preparation

- Removal of sharp objects and debris

- Compaction to specified density

- Moisture content control

- Grading for proper drainage

2. Deployment Techniques

- Unrolling methods to minimize wrinkles and folds

- Temperature considerations for thermal expansion/contraction

- Sequencing for large areas to maintain continuity

3. Seaming Methods

- Thermal Fusion: Most common for polyolefin membranes, creating homogeneous bonds

- Extrusion Welding: For field seams and repairs

- Chemical Adhesives: Used with certain membrane types

- Testing: All seams should be non-destructively tested (air pressure, vacuum) and destructively tested (peel, shear)

4. Protection Measures

- Use of protective geotextiles over the membrane

- Proper cover material placement techniques

- Edge anchoring details

- Protection from construction traffic

Performance in Sewage Treatment Environments

Composite geomembranes perform several critical functions in wastewater treatment facilities:

1. Primary Containment

- Lining for primary treatment tanks and ponds

- Preventing infiltration into groundwater

- Containing raw sewage with high contaminant loads

2. Secondary Treatment Applications

- Anaerobic and aerobic digestion tanks

- Membrane bioreactor systems

- Clarifier basins

3. Sludge Handling

- Drying bed liners

- Sludge storage facilities

- Dewatering operations

4. Effluent Management

- Treated water storage ponds

- Reuse water reservoirs

- Discharge channels

The chemical resistance of composite geomembranes is particularly valuable in these applications, as sewage treatment involves exposure to:

- Sulfides and other corrosive byproducts

- Fluctuating pH conditions

- Biological activity that can degrade inferior materials

- Temperature variations from biological processes

Testing and Quality Assurance

To ensure reliable performance, composite geomembranes for wastewater treatment should meet or exceed relevant international standards:

1. Physical Properties Testing

- Thickness (ASTM D5199)

- Density (ASTM D1505)

- Melt index (ASTM D1238)

2. Mechanical Properties Testing

- Tensile properties (ASTM D6693)

- Tear resistance (ASTM D1004)

- Puncture resistance (ASTM D4833)

- Peel/seam strength (ASTM D6392)

3. Endurance Properties Testing

- Stress cracking resistance (ASTM D5397)

- Oxidative induction time (ASTM D3895)

- UV resistance (ASTM D7238)

4. Hydraulic Properties Testing

- Permeability (ASTM E96)

- Seam integrity (ASTM D5820)

Regular quality control during manufacturing combined with field testing during installation ensures the geomembrane will perform as intended throughout its service life.

Environmental Benefits

The use of durable composite geomembranes in wastewater treatment provides significant environmental advantages:

1. Groundwater Protection: Prevents contamination of underground water resources by creating an impermeable barrier between sewage and the surrounding environment.

2. Soil Protection: Eliminates the migration of contaminants into soils that could affect ecosystems or agricultural productivity.

3. Odor Control: Helps contain volatile compounds that contribute to unpleasant odors from treatment facilities.

4. Resource Conservation: Enables more effective treatment processes by preventing leaks and maintaining system integrity.

5. Long-Term Sustainability: The extended service life reduces the need for frequent replacements, minimizing material consumption and associated environmental impacts.

Cost Considerations

While composite geomembranes represent a significant initial investment, their long-term cost benefits include:

1. Reduced Maintenance: Durable membranes require minimal upkeep compared to alternative lining systems.

2. Extended Service Life: The 30-50 year lifespan provides excellent lifecycle cost efficiency.

3. Risk Mitigation: Prevention of environmental contamination avoids costly remediation and regulatory penalties.

4. Installation Efficiency: Modern composite geomembranes can be installed relatively quickly, reducing labor costs.

The total cost of ownership often proves favorable when considering all operational and environmental factors over the system's lifespan.

Future Developments

Ongoing research and development in composite geomembranes for wastewater treatment focuses on:

1. Enhanced Materials: New polymer formulations with even greater chemical resistance and durability.

2. Smart Membranes: Incorporation of sensors to monitor integrity and detect leaks in real-time.

3. Sustainable Options: Development of bio-based or more easily recyclable membrane materials.

4. Improved Installation Technologies: Advanced seaming methods and deployment techniques to reduce installation time and improve quality.

5. Customized Solutions: Site-specific formulations optimized for particular wastewater chemistries or environmental conditions.

Conclusion

Durable composite geomembranes have become indispensable components in modern wastewater treatment infrastructure. Their unique combination of chemical resistance, mechanical strength, impermeability, and longevity makes them ideally suited for the challenging conditions present in sewage treatment applications. As environmental regulations become more stringent and the need for effective wastewater management grows, these engineered materials will continue to play a vital role in protecting water resources and public health.

Proper material selection, quality manufacturing, and professional installation are all critical to realizing the full potential of composite geomembranes in wastewater treatment. When these factors are addressed, these materials provide reliable, long-term performance that justifies their position as the lining solution of choice for sewage treatment facilities worldwide.

Phone

Phone

Comment

(0)