-

Español

Español

-

Portugues

Portugues

-

Pусский

Pусский

-

Français

Français

-

Deutsch

Deutsch

-

日本語

日本語

-

한국어

한국어

-

العربية

العربية

-

Italiano

Italiano

-

Nederlands

Nederlands

-

Ελληνικά

Ελληνικά

-

Svenska

Svenska

-

Polski

Polski

-

ไทย

ไทย

-

Türk dili

Türk dili

-

हिन्दी

हिन्दी

-

Indonesia

Indonesia

-

Melayu

Melayu

-

Tiếng Việt

Tiếng Việt

-

中文

中文

-

dansk

dansk

-

Magyar

Magyar

-

қазақ

қазақ

-

বাংলা

বাংলা

-

עִברִית

עִברִית

-

čeština

čeština

-

Soomaali

Soomaali

-

မြန်မာ

မြန်မာ

-

فارسی

فارسی

-

українська

українська

-

norsk

norsk

-

Gaeilge

Gaeilge

-

беларускі

беларускі

-

Română

Română

-

ພາສາລາວ

ພາສາລາວ

-

Filipino

Filipino

-

lietuvių

lietuvių

-

Cymraeg

Cymraeg

-

македонски

македонски

-

Suomalainen

Suomalainen

-

slovenský

slovenský

-

o'zbek

o'zbek

-

اردو

اردو

-

հայերեն

հայերեն

-

Igbo

Igbo

-

български

български

-

سنڌي

سنڌي

-

Shona

Shona

-

සිංහල

සිංහල

-

Hrvatski

Hrvatski

-

íslenskur

íslenskur

-

galego

galego

-

català

català

-

Zulu South Africa

Zulu South Africa

-

Afrikaans isiXhosa

Afrikaans isiXhosa

-

ಕನ್ನಡ

ಕನ್ನಡ

-

lëtzebuergesch

lëtzebuergesch

-

Indonésia Sunda

Indonésia Sunda

-

basa jawa

basa jawa

-

ગુજરાતી

ગુજરાતી

-

Кыргызча

Кыргызча

-

тоҷикӣ

тоҷикӣ

-

Србија

Србија

-

Twi

Twi

-

Hawaii

Hawaii

-

Cebu

Cebu

-

नेपाल

नेपाल

-

euskara

euskara

-

Kurdî

Kurdî

-

frissi

frissi

-

יידיש

יידיש

-

latvija

latvija

-

slovenija

slovenija

-

kiswahili

kiswahili

-

ਪੰਜਾਬ

ਪੰਜਾਬ

-

پښتو

پښتو

-

საქართველოს

საქართველოს

-

hua moni

hua moni

-

bosna

bosna

-

తెలుగు

తెలుగు

-

தமிழ்

தமிழ்

-

Kreyòl ayisyen

Kreyòl ayisyen

-

Eesti

Eesti

-

Corsica

Corsica

-

Yoruba

Yoruba

-

Gàidhlig na h-Alba

Gàidhlig na h-Alba

-

Samoa

Samoa

-

Монгол

Монгол

-

Hausa

Hausa

-

Azərbaycan

Azərbaycan

-

አማራ

አማራ

-

Shqipëria

Shqipëria

-

Malagasy

Malagasy

-

मराठी

मराठी

-

മലയാളം

മലയാളം

-

Malta

Malta

-

ខ្មែរ

ខ្មែរ

-

Chicheva

Chicheva

-

中文(繁体)

中文(繁体)

-

ଓଡିଆ

ଓଡିଆ

-

Setswana

Setswana

-

Afrikaans

Afrikaans

-

Aymara

Aymara

-

Башҡорт

Башҡорт

-

Türkmenler

Türkmenler

-

ትግሪኛ

ትግሪኛ

-

Afaan Oromoo

Afaan Oromoo

-

অসমীয়া

অসমীয়া

-

Kinyarwanda

Kinyarwanda

-

Ilocano

Ilocano

-

Wolof

Wolof

-

अवधी

अवधी

-

Oluganda

Oluganda

-

Bikol

Bikol

-

Fulɓe

Fulɓe

-

Kikongo

Kikongo

-

Sango

Sango

-

ދިވެހި

ދިވެހި

-

Lingala

Lingala

-

मैथिली

मैथिली

-

Tsonga

Tsonga

-

ꯃꯦꯏ ꯊꯥꯏ꯫

ꯃꯦꯏ ꯊꯥꯏ꯫

-

brezhoneg

brezhoneg

-

Furlan

Furlan

-

नेवा

नेवा

-

རྫོང་ཁ

རྫོང་ཁ

-

Santali

Santali

-

Аҧсуа

Аҧсуа

-

Нохчийн

Нохчийн

-

Чӑваш

Чӑваш

-

Татар

Татар

-

Batak Karo

Batak Karo

-

دری

دری

-

Diura

Diura

-

Fengyu

Fengyu

-

Eʋegbe

Eʋegbe

-

Iban

Iban

-

Fiji

Fiji

-

Tonga

Tonga

-

Inuktitut

Inuktitut

-

Nahuatl

Nahuatl

-

maaya yucatec

maaya yucatec

-

Runasimi

Runasimi

-

guarani

guarani

-

Qafar

Qafar

-

Acholi

Acholi

-

Dinka

Dinka

-

Luo

Luo

-

Lundi

Lundi

-

isiNdebele

isiNdebele

-

Tshivenḓa

Tshivenḓa

-

Sesotho sa Leboa

Sesotho sa Leboa

-

Sesotho sa Borwa

Sesotho sa Borwa

-

Ndumbe

Ndumbe

-

Papuan Pidgin

Papuan Pidgin

-

Rromani ćhib

Rromani ćhib

-

Thok Nath

Thok Nath

yuxiatugong@163.com

+86 18353494641

-

Español

Español

-

Portugues

Portugues

-

Pусский

Pусский

-

Français

Français

-

Deutsch

Deutsch

-

日本語

日本語

-

한국어

한국어

-

العربية

العربية

-

Italiano

Italiano

-

Nederlands

Nederlands

-

Ελληνικά

Ελληνικά

-

Svenska

Svenska

-

Polski

Polski

-

ไทย

ไทย

-

Türk dili

Türk dili

-

हिन्दी

हिन्दी

-

Indonesia

Indonesia

-

Melayu

Melayu

-

Tiếng Việt

Tiếng Việt

-

中文

中文

-

dansk

dansk

-

Magyar

Magyar

-

қазақ

қазақ

-

বাংলা

বাংলা

-

עִברִית

עִברִית

-

čeština

čeština

-

Soomaali

Soomaali

-

မြန်မာ

မြန်မာ

-

فارسی

فارسی

-

українська

українська

-

norsk

norsk

-

Gaeilge

Gaeilge

-

беларускі

беларускі

-

Română

Română

-

ພາສາລາວ

ພາສາລາວ

-

Filipino

Filipino

-

lietuvių

lietuvių

-

Cymraeg

Cymraeg

-

македонски

македонски

-

Suomalainen

Suomalainen

-

slovenský

slovenský

-

o'zbek

o'zbek

-

اردو

اردو

-

հայերեն

հայերեն

-

Igbo

Igbo

-

български

български

-

سنڌي

سنڌي

-

Shona

Shona

-

සිංහල

සිංහල

-

Hrvatski

Hrvatski

-

íslenskur

íslenskur

-

galego

galego

-

català

català

-

Zulu South Africa

Zulu South Africa

-

Afrikaans isiXhosa

Afrikaans isiXhosa

-

ಕನ್ನಡ

ಕನ್ನಡ

-

lëtzebuergesch

lëtzebuergesch

-

Indonésia Sunda

Indonésia Sunda

-

basa jawa

basa jawa

-

ગુજરાતી

ગુજરાતી

-

Кыргызча

Кыргызча

-

тоҷикӣ

тоҷикӣ

-

Србија

Србија

-

Twi

Twi

-

Hawaii

Hawaii

-

Cebu

Cebu

-

नेपाल

नेपाल

-

euskara

euskara

-

Kurdî

Kurdî

-

frissi

frissi

-

יידיש

יידיש

-

latvija

latvija

-

slovenija

slovenija

-

kiswahili

kiswahili

-

ਪੰਜਾਬ

ਪੰਜਾਬ

-

پښتو

پښتو

-

საქართველოს

საქართველოს

-

hua moni

hua moni

-

bosna

bosna

-

తెలుగు

తెలుగు

-

தமிழ்

தமிழ்

-

Kreyòl ayisyen

Kreyòl ayisyen

-

Eesti

Eesti

-

Corsica

Corsica

-

Yoruba

Yoruba

-

Gàidhlig na h-Alba

Gàidhlig na h-Alba

-

Samoa

Samoa

-

Монгол

Монгол

-

Hausa

Hausa

-

Azərbaycan

Azərbaycan

-

አማራ

አማራ

-

Shqipëria

Shqipëria

-

Malagasy

Malagasy

-

मराठी

मराठी

-

മലയാളം

മലയാളം

-

Malta

Malta

-

ខ្មែរ

ខ្មែរ

-

Chicheva

Chicheva

-

中文(繁体)

中文(繁体)

-

ଓଡିଆ

ଓଡିଆ

-

Setswana

Setswana

-

Afrikaans

Afrikaans

-

Aymara

Aymara

-

Башҡорт

Башҡорт

-

Türkmenler

Türkmenler

-

ትግሪኛ

ትግሪኛ

-

Afaan Oromoo

Afaan Oromoo

-

অসমীয়া

অসমীয়া

-

Kinyarwanda

Kinyarwanda

-

Ilocano

Ilocano

-

Wolof

Wolof

-

अवधी

अवधी

-

Oluganda

Oluganda

-

Bikol

Bikol

-

Fulɓe

Fulɓe

-

Kikongo

Kikongo

-

Sango

Sango

-

ދިވެހި

ދިވެހި

-

Lingala

Lingala

-

मैथिली

मैथिली

-

Tsonga

Tsonga

-

ꯃꯦꯏ ꯊꯥꯏ꯫

ꯃꯦꯏ ꯊꯥꯏ꯫

-

brezhoneg

brezhoneg

-

Furlan

Furlan

-

नेवा

नेवा

-

རྫོང་ཁ

རྫོང་ཁ

-

Santali

Santali

-

Аҧсуа

Аҧсуа

-

Нохчийн

Нохчийн

-

Чӑваш

Чӑваш

-

Татар

Татар

-

Batak Karo

Batak Karo

-

دری

دری

-

Diura

Diura

-

Fengyu

Fengyu

-

Eʋegbe

Eʋegbe

-

Iban

Iban

-

Fiji

Fiji

-

Tonga

Tonga

-

Inuktitut

Inuktitut

-

Nahuatl

Nahuatl

-

maaya yucatec

maaya yucatec

-

Runasimi

Runasimi

-

guarani

guarani

-

Qafar

Qafar

-

Acholi

Acholi

-

Dinka

Dinka

-

Luo

Luo

-

Lundi

Lundi

-

isiNdebele

isiNdebele

-

Tshivenḓa

Tshivenḓa

-

Sesotho sa Leboa

Sesotho sa Leboa

-

Sesotho sa Borwa

Sesotho sa Borwa

-

Ndumbe

Ndumbe

-

Papuan Pidgin

Papuan Pidgin

-

Rromani ćhib

Rromani ćhib

-

Thok Nath

Thok Nath

News Center

News Center

HOT PRODUCT

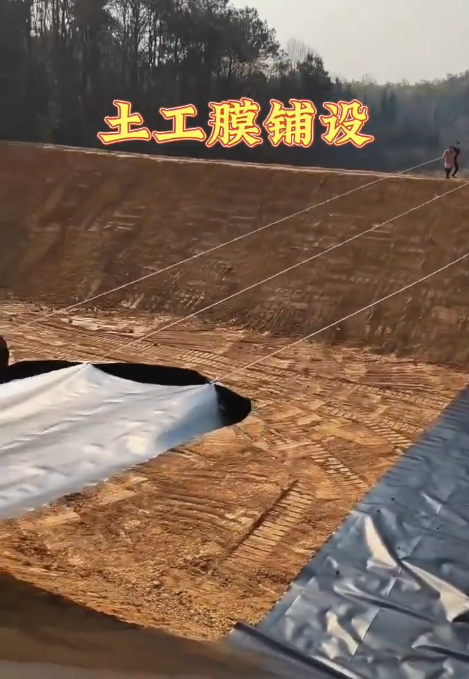

HDPE Composite Geomembrane Liner with Geotextile Backing

2025-10-09 19:24:03

HDPE Composite Geomembrane Liner with Geotextile Backing: A Comprehensive Technical Overview

1. Introduction

High-Density Polyethylene (HDPE) composite geomembrane liners with geotextile backing are engineered materials widely used in environmental, geotechnical, hydraulic, and civil engineering applications. These liners combine the impermeability of HDPE geomembranes with the filtration, drainage, and reinforcement properties of geotextiles, making them ideal for containment, lining, and protection in various projects.

This article provides a detailed examination of HDPE composite geomembrane liners with geotextile backing, covering their composition, manufacturing process, key properties, applications, installation methods, and advantages.

2. Composition and Structure

2.1 HDPE Geomembrane Layer

The primary component of the composite liner is the HDPE geomembrane, which serves as the impermeable barrier. HDPE is a thermoplastic polymer known for its high strength, chemical resistance, and durability. Key characteristics include:

- Material Properties: High tensile strength, puncture resistance, and flexibility.

- Chemical Resistance: Resistant to acids, alkalis, and most industrial chemicals.

- UV Resistance: When formulated with carbon black, HDPE geomembranes exhibit excellent UV stability.

- Temperature Tolerance: Performs well in a wide temperature range (-60°C to +80°C).

2.2 Geotextile Backing Layer

The geotextile layer is typically a non-woven or woven fabric made from synthetic fibers such as polyester or polypropylene. Its functions include:

- Filtration: Prevents soil migration while allowing water passage.

- Drainage: Facilitates lateral water flow, reducing hydrostatic pressure.

- Protection: Shields the geomembrane from punctures and abrasion.

- Reinforcement: Enhances the structural stability of the composite liner.

2.3 Bonding Mechanism

The HDPE geomembrane and geotextile are bonded using thermal lamination or adhesive methods to ensure a strong, durable composite structure. The bonding must withstand mechanical stresses and environmental exposure without delamination.

3. Manufacturing Process

The production of HDPE composite geomembrane liners involves several key steps:

1. HDPE Sheet Extrusion: HDPE resin is melted and extruded into flat sheets of uniform thickness.

2. Geotextile Preparation: Non-woven or woven geotextiles are prepared and cleaned.

3. Lamination: The HDPE sheet and geotextile are thermally bonded under controlled heat and pressure.

4. Quality Control: The composite liner undergoes rigorous testing for thickness, tensile strength, peel strength, and seam integrity.

5. Rolling and Packaging: The finished product is rolled and packaged for transportation.

4. Key Properties and Performance Characteristics

4.1 Physical Properties

- Thickness: Typically ranges from 0.5 mm to 3.0 mm.

- Density: HDPE density is around 0.94–0.96 g/cm³.

- Tensile Strength: High tensile strength (≥20 MPa) ensures resistance to mechanical stresses.

4.2 Hydraulic Properties

- Permeability: Extremely low (≤1×10⁻¹² cm/s), making it nearly impermeable to liquids and gases.

- Puncture Resistance: The geotextile backing enhances resistance to punctures from sharp objects.

4.3 Environmental Resistance

- Chemical Resistance: Resistant to hydrocarbons, acids, alkalis, and salts.

- UV Stability: Carbon black additives improve long-term UV resistance.

- Thermal Stability: Maintains performance in extreme temperatures.

4.4 Durability and Longevity

- Service Life: Can exceed 50 years under proper installation and environmental conditions.

- Aging Resistance: Resistant to oxidative degradation and biological attack.

5. Applications

HDPE composite geomembrane liners with geotextile backing are used in various industries, including:

5.1 Environmental Engineering

- Landfill Liners: Prevent leachate migration into groundwater.

- Containment Ponds: Used in mining, wastewater treatment, and industrial storage.

- Secondary Containment: For fuel storage tanks and chemical facilities.

5.2 Water Management

- Reservoirs and Canals: Prevent seepage and water loss.

- Decorative Ponds and Lakes: Provide waterproofing and erosion control.

5.3 Mining and Industrial Applications

- Heap Leach Pads: Contain chemical solutions in metal extraction.

- Tailings Storage: Prevent contamination from mining waste.

5.4 Civil Engineering

- Tunnel Linings: Waterproofing and structural reinforcement.

- Road and Railway Embankments: Improve stability and drainage.

6. Installation Guidelines

Proper installation is critical to the performance of HDPE composite geomembrane liners. Key steps include:

6.1 Subgrade Preparation

- Remove sharp objects, rocks, and debris.

- Compact and level the subgrade to avoid punctures.

6.2 Unrolling and Positioning

- Unroll the liner carefully to avoid wrinkles and folds.

- Allow for thermal expansion by leaving slack.

6.3 Seaming Techniques

- Thermal Welding: Uses hot wedge or extrusion welding for strong, leak-proof seams.

- Adhesive Bonding: Suitable for small repairs or difficult-to-weld areas.

6.4 Anchoring and Protection

- Secure edges with trench anchors or ballast.

- Cover with protective soil or geotextile to prevent UV degradation.

7. Advantages of HDPE Composite Geomembrane Liners

- Superior Impermeability: Effective containment of liquids and gases.

- Enhanced Durability: Resistant to punctures, chemicals, and UV exposure.

- Cost-Effective: Long service life reduces maintenance and replacement costs.

- Versatility: Suitable for a wide range of applications.

- Ease of Installation: Lightweight and flexible for efficient deployment.

8. Conclusion

HDPE composite geomembrane liners with geotextile backing are a highly effective solution for containment, waterproofing, and reinforcement in engineering projects. Their combination of impermeability, strength, and environmental resistance makes them indispensable in landfill construction, water management, mining, and civil infrastructure.

By following proper manufacturing and installation practices, these liners provide long-term performance, ensuring environmental protection and structural integrity. Future advancements in polymer technology and geosynthetics will further enhance their capabilities, expanding their use in sustainable engineering solutions.

---

This article provides a comprehensive technical overview of HDPE composite geomembrane liners with geotextile backing, covering their properties, applications, and installation best practices. Let me know if you need any modifications or additional details.

Phone

Phone

Comment

(0)