-

Español

Español

-

Portugues

Portugues

-

Pусский

Pусский

-

Français

Français

-

Deutsch

Deutsch

-

日本語

日本語

-

한국어

한국어

-

العربية

العربية

-

Italiano

Italiano

-

Nederlands

Nederlands

-

Ελληνικά

Ελληνικά

-

Svenska

Svenska

-

Polski

Polski

-

ไทย

ไทย

-

Türk dili

Türk dili

-

हिन्दी

हिन्दी

-

Indonesia

Indonesia

-

Melayu

Melayu

-

Tiếng Việt

Tiếng Việt

-

中文

中文

-

dansk

dansk

-

Magyar

Magyar

-

қазақ

қазақ

-

বাংলা

বাংলা

-

עִברִית

עִברִית

-

čeština

čeština

-

Soomaali

Soomaali

-

မြန်မာ

မြန်မာ

-

فارسی

فارسی

-

українська

українська

-

norsk

norsk

-

Gaeilge

Gaeilge

-

беларускі

беларускі

-

Română

Română

-

ພາສາລາວ

ພາສາລາວ

-

Filipino

Filipino

-

lietuvių

lietuvių

-

Cymraeg

Cymraeg

-

македонски

македонски

-

Suomalainen

Suomalainen

-

slovenský

slovenský

-

o'zbek

o'zbek

-

اردو

اردو

-

հայերեն

հայերեն

-

Igbo

Igbo

-

български

български

-

سنڌي

سنڌي

-

Shona

Shona

-

සිංහල

සිංහල

-

Hrvatski

Hrvatski

-

íslenskur

íslenskur

-

galego

galego

-

català

català

-

Zulu South Africa

Zulu South Africa

-

Afrikaans isiXhosa

Afrikaans isiXhosa

-

ಕನ್ನಡ

ಕನ್ನಡ

-

lëtzebuergesch

lëtzebuergesch

-

Indonésia Sunda

Indonésia Sunda

-

basa jawa

basa jawa

-

ગુજરાતી

ગુજરાતી

-

Кыргызча

Кыргызча

-

тоҷикӣ

тоҷикӣ

-

Србија

Србија

-

Twi

Twi

-

Hawaii

Hawaii

-

Cebu

Cebu

-

नेपाल

नेपाल

-

euskara

euskara

-

Kurdî

Kurdî

-

frissi

frissi

-

יידיש

יידיש

-

latvija

latvija

-

slovenija

slovenija

-

kiswahili

kiswahili

-

ਪੰਜਾਬ

ਪੰਜਾਬ

-

پښتو

پښتو

-

საქართველოს

საქართველოს

-

hua moni

hua moni

-

bosna

bosna

-

తెలుగు

తెలుగు

-

தமிழ்

தமிழ்

-

Kreyòl ayisyen

Kreyòl ayisyen

-

Eesti

Eesti

-

Corsica

Corsica

-

Yoruba

Yoruba

-

Gàidhlig na h-Alba

Gàidhlig na h-Alba

-

Samoa

Samoa

-

Монгол

Монгол

-

Hausa

Hausa

-

Azərbaycan

Azərbaycan

-

አማራ

አማራ

-

Shqipëria

Shqipëria

-

Malagasy

Malagasy

-

मराठी

मराठी

-

മലയാളം

മലയാളം

-

Malta

Malta

-

ខ្មែរ

ខ្មែរ

-

Chicheva

Chicheva

-

中文(繁体)

中文(繁体)

-

ଓଡିଆ

ଓଡିଆ

-

Setswana

Setswana

-

Afrikaans

Afrikaans

-

Aymara

Aymara

-

Башҡорт

Башҡорт

-

Türkmenler

Türkmenler

-

ትግሪኛ

ትግሪኛ

-

Afaan Oromoo

Afaan Oromoo

-

অসমীয়া

অসমীয়া

-

Kinyarwanda

Kinyarwanda

-

Ilocano

Ilocano

-

Wolof

Wolof

-

अवधी

अवधी

-

Oluganda

Oluganda

-

Bikol

Bikol

-

Fulɓe

Fulɓe

-

Kikongo

Kikongo

-

Sango

Sango

-

ދިވެހި

ދިވެހި

-

Lingala

Lingala

-

मैथिली

मैथिली

-

Tsonga

Tsonga

-

ꯃꯦꯏ ꯊꯥꯏ꯫

ꯃꯦꯏ ꯊꯥꯏ꯫

-

brezhoneg

brezhoneg

-

Furlan

Furlan

-

नेवा

नेवा

-

རྫོང་ཁ

རྫོང་ཁ

-

Santali

Santali

-

Аҧсуа

Аҧсуа

-

Нохчийн

Нохчийн

-

Чӑваш

Чӑваш

-

Татар

Татар

-

Batak Karo

Batak Karo

-

دری

دری

-

Diura

Diura

-

Fengyu

Fengyu

-

Eʋegbe

Eʋegbe

-

Iban

Iban

-

Fiji

Fiji

-

Tonga

Tonga

-

Inuktitut

Inuktitut

-

Nahuatl

Nahuatl

-

maaya yucatec

maaya yucatec

-

Runasimi

Runasimi

-

guarani

guarani

-

Qafar

Qafar

-

Acholi

Acholi

-

Dinka

Dinka

-

Luo

Luo

-

Lundi

Lundi

-

isiNdebele

isiNdebele

-

Tshivenḓa

Tshivenḓa

-

Sesotho sa Leboa

Sesotho sa Leboa

-

Sesotho sa Borwa

Sesotho sa Borwa

-

Ndumbe

Ndumbe

-

Papuan Pidgin

Papuan Pidgin

-

Rromani ćhib

Rromani ćhib

-

Thok Nath

Thok Nath

yuxiatugong@163.com

+86 18353494641

-

Español

Español

-

Portugues

Portugues

-

Pусский

Pусский

-

Français

Français

-

Deutsch

Deutsch

-

日本語

日本語

-

한국어

한국어

-

العربية

العربية

-

Italiano

Italiano

-

Nederlands

Nederlands

-

Ελληνικά

Ελληνικά

-

Svenska

Svenska

-

Polski

Polski

-

ไทย

ไทย

-

Türk dili

Türk dili

-

हिन्दी

हिन्दी

-

Indonesia

Indonesia

-

Melayu

Melayu

-

Tiếng Việt

Tiếng Việt

-

中文

中文

-

dansk

dansk

-

Magyar

Magyar

-

қазақ

қазақ

-

বাংলা

বাংলা

-

עִברִית

עִברִית

-

čeština

čeština

-

Soomaali

Soomaali

-

မြန်မာ

မြန်မာ

-

فارسی

فارسی

-

українська

українська

-

norsk

norsk

-

Gaeilge

Gaeilge

-

беларускі

беларускі

-

Română

Română

-

ພາສາລາວ

ພາສາລາວ

-

Filipino

Filipino

-

lietuvių

lietuvių

-

Cymraeg

Cymraeg

-

македонски

македонски

-

Suomalainen

Suomalainen

-

slovenský

slovenský

-

o'zbek

o'zbek

-

اردو

اردو

-

հայերեն

հայերեն

-

Igbo

Igbo

-

български

български

-

سنڌي

سنڌي

-

Shona

Shona

-

සිංහල

සිංහල

-

Hrvatski

Hrvatski

-

íslenskur

íslenskur

-

galego

galego

-

català

català

-

Zulu South Africa

Zulu South Africa

-

Afrikaans isiXhosa

Afrikaans isiXhosa

-

ಕನ್ನಡ

ಕನ್ನಡ

-

lëtzebuergesch

lëtzebuergesch

-

Indonésia Sunda

Indonésia Sunda

-

basa jawa

basa jawa

-

ગુજરાતી

ગુજરાતી

-

Кыргызча

Кыргызча

-

тоҷикӣ

тоҷикӣ

-

Србија

Србија

-

Twi

Twi

-

Hawaii

Hawaii

-

Cebu

Cebu

-

नेपाल

नेपाल

-

euskara

euskara

-

Kurdî

Kurdî

-

frissi

frissi

-

יידיש

יידיש

-

latvija

latvija

-

slovenija

slovenija

-

kiswahili

kiswahili

-

ਪੰਜਾਬ

ਪੰਜਾਬ

-

پښتو

پښتو

-

საქართველოს

საქართველოს

-

hua moni

hua moni

-

bosna

bosna

-

తెలుగు

తెలుగు

-

தமிழ்

தமிழ்

-

Kreyòl ayisyen

Kreyòl ayisyen

-

Eesti

Eesti

-

Corsica

Corsica

-

Yoruba

Yoruba

-

Gàidhlig na h-Alba

Gàidhlig na h-Alba

-

Samoa

Samoa

-

Монгол

Монгол

-

Hausa

Hausa

-

Azərbaycan

Azərbaycan

-

አማራ

አማራ

-

Shqipëria

Shqipëria

-

Malagasy

Malagasy

-

मराठी

मराठी

-

മലയാളം

മലയാളം

-

Malta

Malta

-

ខ្មែរ

ខ្មែរ

-

Chicheva

Chicheva

-

中文(繁体)

中文(繁体)

-

ଓଡିଆ

ଓଡିଆ

-

Setswana

Setswana

-

Afrikaans

Afrikaans

-

Aymara

Aymara

-

Башҡорт

Башҡорт

-

Türkmenler

Türkmenler

-

ትግሪኛ

ትግሪኛ

-

Afaan Oromoo

Afaan Oromoo

-

অসমীয়া

অসমীয়া

-

Kinyarwanda

Kinyarwanda

-

Ilocano

Ilocano

-

Wolof

Wolof

-

अवधी

अवधी

-

Oluganda

Oluganda

-

Bikol

Bikol

-

Fulɓe

Fulɓe

-

Kikongo

Kikongo

-

Sango

Sango

-

ދިވެހި

ދިވެހި

-

Lingala

Lingala

-

मैथिली

मैथिली

-

Tsonga

Tsonga

-

ꯃꯦꯏ ꯊꯥꯏ꯫

ꯃꯦꯏ ꯊꯥꯏ꯫

-

brezhoneg

brezhoneg

-

Furlan

Furlan

-

नेवा

नेवा

-

རྫོང་ཁ

རྫོང་ཁ

-

Santali

Santali

-

Аҧсуа

Аҧсуа

-

Нохчийн

Нохчийн

-

Чӑваш

Чӑваш

-

Татар

Татар

-

Batak Karo

Batak Karo

-

دری

دری

-

Diura

Diura

-

Fengyu

Fengyu

-

Eʋegbe

Eʋegbe

-

Iban

Iban

-

Fiji

Fiji

-

Tonga

Tonga

-

Inuktitut

Inuktitut

-

Nahuatl

Nahuatl

-

maaya yucatec

maaya yucatec

-

Runasimi

Runasimi

-

guarani

guarani

-

Qafar

Qafar

-

Acholi

Acholi

-

Dinka

Dinka

-

Luo

Luo

-

Lundi

Lundi

-

isiNdebele

isiNdebele

-

Tshivenḓa

Tshivenḓa

-

Sesotho sa Leboa

Sesotho sa Leboa

-

Sesotho sa Borwa

Sesotho sa Borwa

-

Ndumbe

Ndumbe

-

Papuan Pidgin

Papuan Pidgin

-

Rromani ćhib

Rromani ćhib

-

Thok Nath

Thok Nath

News Center

News Center

HOT PRODUCT

Reinforced Road Construction Concrete Canvas Heavy Duty Patch

2025-10-10 04:11:54

Reinforced Road Construction: The Advantages of Heavy-Duty Concrete Canvas Patching

Introduction

Road infrastructure is critical for economic development, transportation efficiency, and public safety. However, roads are subject to constant wear and tear due to heavy traffic, weather conditions, and aging materials. Traditional road repair methods, such as asphalt patching or conventional concrete pouring, often require extensive labor, time, and resources. In recent years, innovative materials like Concrete Canvas (CC) have emerged as a high-performance solution for rapid and durable road repairs.

This article explores reinforced road construction using heavy-duty Concrete Canvas patches, focusing on their composition, installation process, advantages, and applications in modern infrastructure maintenance.

---

1. What is Concrete Canvas?

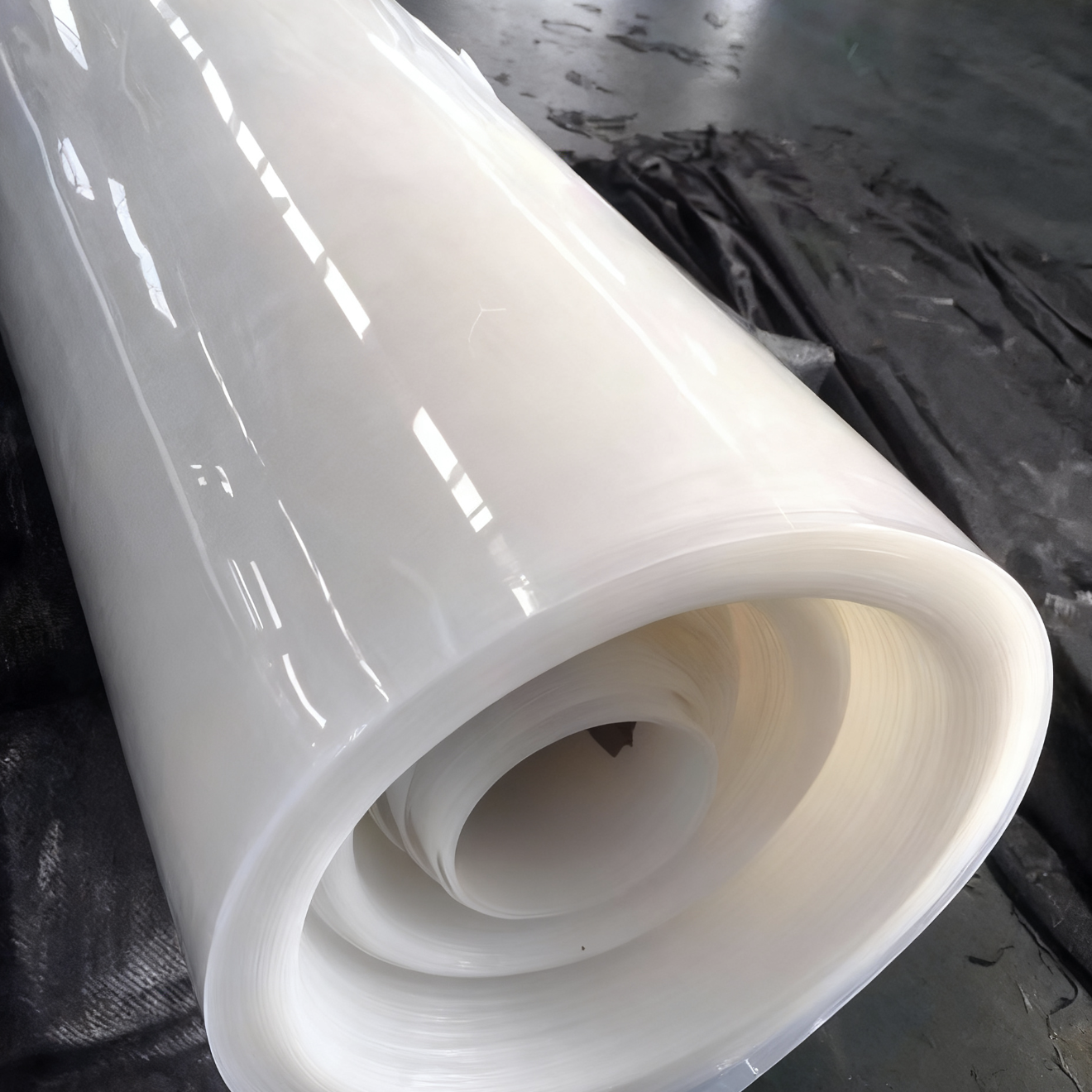

Concrete Canvas is a flexible, cement-impregnated fabric that hardens upon hydration to form a thin, durable concrete layer. It consists of a three-dimensional fiber matrix containing a specially formulated dry concrete mix. When water is applied, the material cures rapidly, creating a robust, crack-resistant surface.

For heavy-duty road patching, Concrete Canvas is reinforced with additional layers of high-strength geotextile or fiberglass mesh to enhance load-bearing capacity and resistance to dynamic stresses.

---

2. Key Features of Heavy-Duty Concrete Canvas Patches

2.1 Rapid Installation

Unlike traditional concrete, which requires mixing, pouring, and days of curing, Concrete Canvas can be deployed in minutes. The material is rolled out over the damaged area, hydrated with water, and left to cure—typically reaching 80% strength within 24 hours.

2.2 High Durability

Reinforced Concrete Canvas patches are designed to withstand heavy traffic loads, including trucks and industrial vehicles. The material resists cracking, erosion, and chemical degradation from road salts or oils.

2.3 Flexibility Before Curing

Before hydration, the fabric remains flexible, allowing it to conform to irregular surfaces, potholes, or uneven substrates without requiring extensive preparation.

2.4 Minimal Equipment and Labor

The installation process eliminates the need for heavy machinery, reducing labor costs and traffic disruption.

2.5 Weather Resistance

Concrete Canvas cures even in wet or cold conditions, making it suitable for emergency repairs during adverse weather.

---

3. Applications in Road Construction

3.1 Pothole Repair

Potholes are a common road hazard that can damage vehicles and cause accidents. Heavy-duty Concrete Canvas patches provide an immediate, long-lasting solution without the need for excavation or compaction.

3.2 Bridge Deck Repairs

Reinforced Concrete Canvas can be used to repair deteriorating bridge surfaces, providing a waterproof, skid-resistant layer that extends the structure’s lifespan.

3.3 Temporary Roadways

In construction zones or disaster-stricken areas, Concrete Canvas can create instant temporary road surfaces capable of supporting heavy equipment.

3.4 Erosion Control

On slopes or embankments adjacent to roads, the material prevents soil erosion while offering structural reinforcement.

---

4. Installation Process

1. Surface Preparation

- Remove loose debris and clean the repair area.

- No extensive leveling is required due to the material’s flexibility.

2. Unrolling and Cutting

- The reinforced Concrete Canvas is cut to size and laid over the damaged section.

3. Hydration

- Water is sprayed or poured evenly over the fabric, triggering the curing process.

4. Curing

- The material hardens within hours, with full strength achieved in 24–48 hours.

5. Traffic Reopening

- Light traffic can often resume within hours; heavy vehicles may require a short waiting period.

---

5. Advantages Over Traditional Methods

| Factor | Concrete Canvas | Traditional Concrete/Asphalt |

|--------------------------|----------------------------------|----------------------------------|

| Curing Time | Hours to 1 day | 3–7 days |

| Labor Requirements | Minimal (1–2 workers) | Heavy machinery, multiple crews |

| Weather Sensitivity | Cures in rain or cold | Delays in wet/freezing conditions|

| Longevity | Resists cracks and wear | Prone to cracks over time |

| Eco-Friendliness | Low waste, no excess runoff | High material waste |

---

6. Environmental and Economic Benefits

- Reduced Carbon Footprint: Faster repairs mean fewer traffic delays, lowering vehicle emissions.

- Less Material Waste: Pre-measured fabric minimizes excess concrete use.

- Lower Lifetime Costs: Durable patches reduce the frequency of repairs.

---

7. Challenges and Considerations

- Initial Cost: While material costs may be higher than asphalt, long-term savings offset this.

- Skill Requirements: Proper installation techniques are crucial for optimal performance.

- Load Limits: Ultra-heavy industrial zones may require additional reinforcement.

---

8. Future Developments

Ongoing research aims to enhance Concrete Canvas with:

- Self-healing properties (using bacteria or polymers).

- Smart sensors to monitor structural health.

- Thicker, ultra-high-strength variants for airport runways.

---

Conclusion

Reinforced Concrete Canvas represents a revolutionary advancement in road construction and maintenance. Its speed, durability, and ease of use make it an ideal solution for heavy-duty patching, reducing downtime and improving infrastructure resilience. As technology evolves, this material is poised to become a standard in sustainable road repair worldwide.

By adopting innovative solutions like Concrete Canvas, governments and construction agencies can address road deterioration more efficiently, ensuring safer, longer-lasting transportation networks for the future.

(Word count: ~2000)

Phone

Phone

Comment

(0)