-

Español

Español

-

Portugues

Portugues

-

Pусский

Pусский

-

Français

Français

-

Deutsch

Deutsch

-

日本語

日本語

-

한국어

한국어

-

العربية

العربية

-

Italiano

Italiano

-

Nederlands

Nederlands

-

Ελληνικά

Ελληνικά

-

Svenska

Svenska

-

Polski

Polski

-

ไทย

ไทย

-

Türk dili

Türk dili

-

हिन्दी

हिन्दी

-

Indonesia

Indonesia

-

Melayu

Melayu

-

Tiếng Việt

Tiếng Việt

-

中文

中文

-

dansk

dansk

-

Magyar

Magyar

-

қазақ

қазақ

-

বাংলা

বাংলা

-

עִברִית

עִברִית

-

čeština

čeština

-

Soomaali

Soomaali

-

မြန်မာ

မြန်မာ

-

فارسی

فارسی

-

українська

українська

-

norsk

norsk

-

Gaeilge

Gaeilge

-

беларускі

беларускі

-

Română

Română

-

ພາສາລາວ

ພາສາລາວ

-

Filipino

Filipino

-

lietuvių

lietuvių

-

Cymraeg

Cymraeg

-

македонски

македонски

-

Suomalainen

Suomalainen

-

slovenský

slovenský

-

o'zbek

o'zbek

-

اردو

اردو

-

հայերեն

հայերեն

-

Igbo

Igbo

-

български

български

-

سنڌي

سنڌي

-

Shona

Shona

-

සිංහල

සිංහල

-

Hrvatski

Hrvatski

-

íslenskur

íslenskur

-

galego

galego

-

català

català

-

Zulu South Africa

Zulu South Africa

-

Afrikaans isiXhosa

Afrikaans isiXhosa

-

ಕನ್ನಡ

ಕನ್ನಡ

-

lëtzebuergesch

lëtzebuergesch

-

Indonésia Sunda

Indonésia Sunda

-

basa jawa

basa jawa

-

ગુજરાતી

ગુજરાતી

-

Кыргызча

Кыргызча

-

тоҷикӣ

тоҷикӣ

-

Србија

Србија

-

Twi

Twi

-

Hawaii

Hawaii

-

Cebu

Cebu

-

नेपाल

नेपाल

-

euskara

euskara

-

Kurdî

Kurdî

-

frissi

frissi

-

יידיש

יידיש

-

latvija

latvija

-

slovenija

slovenija

-

kiswahili

kiswahili

-

ਪੰਜਾਬ

ਪੰਜਾਬ

-

پښتو

پښتو

-

საქართველოს

საქართველოს

-

hua moni

hua moni

-

bosna

bosna

-

తెలుగు

తెలుగు

-

தமிழ்

தமிழ்

-

Kreyòl ayisyen

Kreyòl ayisyen

-

Eesti

Eesti

-

Corsica

Corsica

-

Yoruba

Yoruba

-

Gàidhlig na h-Alba

Gàidhlig na h-Alba

-

Samoa

Samoa

-

Монгол

Монгол

-

Hausa

Hausa

-

Azərbaycan

Azərbaycan

-

አማራ

አማራ

-

Shqipëria

Shqipëria

-

Malagasy

Malagasy

-

मराठी

मराठी

-

മലയാളം

മലയാളം

-

Malta

Malta

-

ខ្មែរ

ខ្មែរ

-

Chicheva

Chicheva

-

中文(繁体)

中文(繁体)

-

ଓଡିଆ

ଓଡିଆ

-

Setswana

Setswana

-

Afrikaans

Afrikaans

-

Aymara

Aymara

-

Башҡорт

Башҡорт

-

Türkmenler

Türkmenler

-

ትግሪኛ

ትግሪኛ

-

Afaan Oromoo

Afaan Oromoo

-

অসমীয়া

অসমীয়া

-

Kinyarwanda

Kinyarwanda

-

Ilocano

Ilocano

-

Wolof

Wolof

-

अवधी

अवधी

-

Oluganda

Oluganda

-

Bikol

Bikol

-

Fulɓe

Fulɓe

-

Kikongo

Kikongo

-

Sango

Sango

-

ދިވެހި

ދިވެހި

-

Lingala

Lingala

-

मैथिली

मैथिली

-

Tsonga

Tsonga

-

ꯃꯦꯏ ꯊꯥꯏ꯫

ꯃꯦꯏ ꯊꯥꯏ꯫

-

brezhoneg

brezhoneg

-

Furlan

Furlan

-

नेवा

नेवा

-

རྫོང་ཁ

རྫོང་ཁ

-

Santali

Santali

-

Аҧсуа

Аҧсуа

-

Нохчийн

Нохчийн

-

Чӑваш

Чӑваш

-

Татар

Татар

-

Batak Karo

Batak Karo

-

دری

دری

-

Diura

Diura

-

Fengyu

Fengyu

-

Eʋegbe

Eʋegbe

-

Iban

Iban

-

Fiji

Fiji

-

Tonga

Tonga

-

Inuktitut

Inuktitut

-

Nahuatl

Nahuatl

-

maaya yucatec

maaya yucatec

-

Runasimi

Runasimi

-

guarani

guarani

-

Qafar

Qafar

-

Acholi

Acholi

-

Dinka

Dinka

-

Luo

Luo

-

Lundi

Lundi

-

isiNdebele

isiNdebele

-

Tshivenḓa

Tshivenḓa

-

Sesotho sa Leboa

Sesotho sa Leboa

-

Sesotho sa Borwa

Sesotho sa Borwa

-

Ndumbe

Ndumbe

-

Papuan Pidgin

Papuan Pidgin

-

Rromani ćhib

Rromani ćhib

-

Thok Nath

Thok Nath

yuxiatugong@163.com

+86 18353494641

-

Español

Español

-

Portugues

Portugues

-

Pусский

Pусский

-

Français

Français

-

Deutsch

Deutsch

-

日本語

日本語

-

한국어

한국어

-

العربية

العربية

-

Italiano

Italiano

-

Nederlands

Nederlands

-

Ελληνικά

Ελληνικά

-

Svenska

Svenska

-

Polski

Polski

-

ไทย

ไทย

-

Türk dili

Türk dili

-

हिन्दी

हिन्दी

-

Indonesia

Indonesia

-

Melayu

Melayu

-

Tiếng Việt

Tiếng Việt

-

中文

中文

-

dansk

dansk

-

Magyar

Magyar

-

қазақ

қазақ

-

বাংলা

বাংলা

-

עִברִית

עִברִית

-

čeština

čeština

-

Soomaali

Soomaali

-

မြန်မာ

မြန်မာ

-

فارسی

فارسی

-

українська

українська

-

norsk

norsk

-

Gaeilge

Gaeilge

-

беларускі

беларускі

-

Română

Română

-

ພາສາລາວ

ພາສາລາວ

-

Filipino

Filipino

-

lietuvių

lietuvių

-

Cymraeg

Cymraeg

-

македонски

македонски

-

Suomalainen

Suomalainen

-

slovenský

slovenský

-

o'zbek

o'zbek

-

اردو

اردو

-

հայերեն

հայերեն

-

Igbo

Igbo

-

български

български

-

سنڌي

سنڌي

-

Shona

Shona

-

සිංහල

සිංහල

-

Hrvatski

Hrvatski

-

íslenskur

íslenskur

-

galego

galego

-

català

català

-

Zulu South Africa

Zulu South Africa

-

Afrikaans isiXhosa

Afrikaans isiXhosa

-

ಕನ್ನಡ

ಕನ್ನಡ

-

lëtzebuergesch

lëtzebuergesch

-

Indonésia Sunda

Indonésia Sunda

-

basa jawa

basa jawa

-

ગુજરાતી

ગુજરાતી

-

Кыргызча

Кыргызча

-

тоҷикӣ

тоҷикӣ

-

Србија

Србија

-

Twi

Twi

-

Hawaii

Hawaii

-

Cebu

Cebu

-

नेपाल

नेपाल

-

euskara

euskara

-

Kurdî

Kurdî

-

frissi

frissi

-

יידיש

יידיש

-

latvija

latvija

-

slovenija

slovenija

-

kiswahili

kiswahili

-

ਪੰਜਾਬ

ਪੰਜਾਬ

-

پښتو

پښتو

-

საქართველოს

საქართველოს

-

hua moni

hua moni

-

bosna

bosna

-

తెలుగు

తెలుగు

-

தமிழ்

தமிழ்

-

Kreyòl ayisyen

Kreyòl ayisyen

-

Eesti

Eesti

-

Corsica

Corsica

-

Yoruba

Yoruba

-

Gàidhlig na h-Alba

Gàidhlig na h-Alba

-

Samoa

Samoa

-

Монгол

Монгол

-

Hausa

Hausa

-

Azərbaycan

Azərbaycan

-

አማራ

አማራ

-

Shqipëria

Shqipëria

-

Malagasy

Malagasy

-

मराठी

मराठी

-

മലയാളം

മലയാളം

-

Malta

Malta

-

ខ្មែរ

ខ្មែរ

-

Chicheva

Chicheva

-

中文(繁体)

中文(繁体)

-

ଓଡିଆ

ଓଡିଆ

-

Setswana

Setswana

-

Afrikaans

Afrikaans

-

Aymara

Aymara

-

Башҡорт

Башҡорт

-

Türkmenler

Türkmenler

-

ትግሪኛ

ትግሪኛ

-

Afaan Oromoo

Afaan Oromoo

-

অসমীয়া

অসমীয়া

-

Kinyarwanda

Kinyarwanda

-

Ilocano

Ilocano

-

Wolof

Wolof

-

अवधी

अवधी

-

Oluganda

Oluganda

-

Bikol

Bikol

-

Fulɓe

Fulɓe

-

Kikongo

Kikongo

-

Sango

Sango

-

ދިވެހި

ދިވެހި

-

Lingala

Lingala

-

मैथिली

मैथिली

-

Tsonga

Tsonga

-

ꯃꯦꯏ ꯊꯥꯏ꯫

ꯃꯦꯏ ꯊꯥꯏ꯫

-

brezhoneg

brezhoneg

-

Furlan

Furlan

-

नेवा

नेवा

-

རྫོང་ཁ

རྫོང་ཁ

-

Santali

Santali

-

Аҧсуа

Аҧсуа

-

Нохчийн

Нохчийн

-

Чӑваш

Чӑваш

-

Татар

Татар

-

Batak Karo

Batak Karo

-

دری

دری

-

Diura

Diura

-

Fengyu

Fengyu

-

Eʋegbe

Eʋegbe

-

Iban

Iban

-

Fiji

Fiji

-

Tonga

Tonga

-

Inuktitut

Inuktitut

-

Nahuatl

Nahuatl

-

maaya yucatec

maaya yucatec

-

Runasimi

Runasimi

-

guarani

guarani

-

Qafar

Qafar

-

Acholi

Acholi

-

Dinka

Dinka

-

Luo

Luo

-

Lundi

Lundi

-

isiNdebele

isiNdebele

-

Tshivenḓa

Tshivenḓa

-

Sesotho sa Leboa

Sesotho sa Leboa

-

Sesotho sa Borwa

Sesotho sa Borwa

-

Ndumbe

Ndumbe

-

Papuan Pidgin

Papuan Pidgin

-

Rromani ćhib

Rromani ćhib

-

Thok Nath

Thok Nath

News Center

News Center

HOT PRODUCT

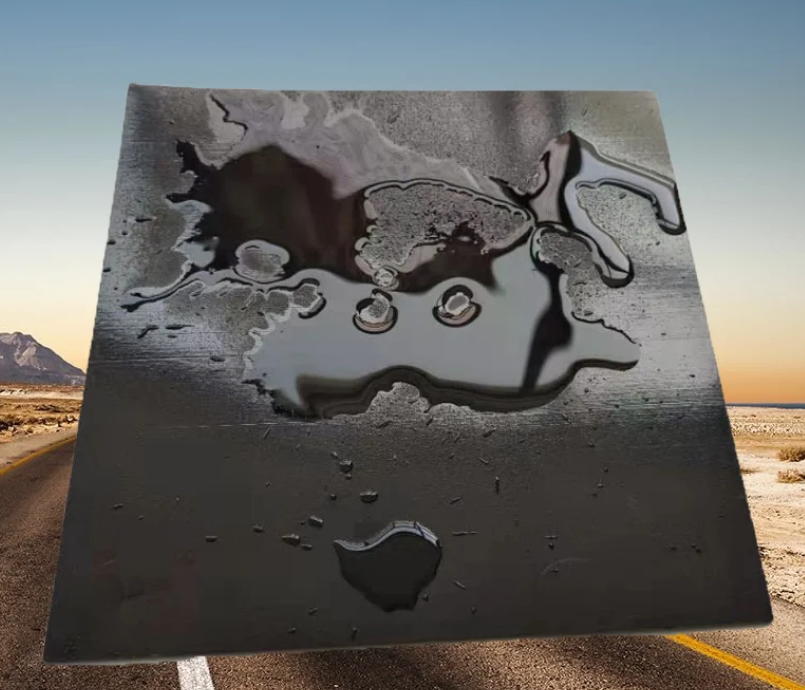

Waterproof Sheet Material for Tunnels and Underground Works

2025-10-16 08:04:29

Waterproof Sheet Materials for Tunnels and Underground Works

Introduction

Waterproofing is a critical component in the construction and maintenance of tunnels and underground structures. Without proper waterproofing, these structures are vulnerable to water infiltration, which can lead to structural deterioration, corrosion of reinforcement, reduced service life, and increased maintenance costs. Waterproof sheet materials play a pivotal role in creating an effective barrier against water penetration in underground environments. This paper explores the various types of waterproof sheet materials used in tunnel and underground construction, their properties, installation methods, and performance considerations.

Types of Waterproof Sheet Materials

1. Thermoplastic Membranes

Thermoplastic waterproofing membranes are among the most commonly used materials in tunnel waterproofing applications. These sheets are typically made from polyvinyl chloride (PVC), thermoplastic polyolefin (TPO), or polyethylene (PE) compounds.

PVC Membranes:

- Composed of polyvinyl chloride with plasticizers and stabilizers

- Flexible and durable with good puncture resistance

- Available in various thicknesses (typically 1.2mm to 2.0mm)

- Can be welded at seams for continuous waterproofing

- Resistant to most chemicals found in groundwater

TPO Membranes:

- Blend of polypropylene and ethylene-propylene rubber

- Excellent heat resistance and UV stability (for exposed applications)

- Environmentally friendly as they contain no plasticizers

- Highly flexible at low temperatures

PE Membranes:

- High-density polyethylene (HDPE) or low-density polyethylene (LDPE)

- Excellent chemical resistance

- High tensile strength

- Lightweight and easy to handle

2. Bituminous Membranes

Bituminous waterproofing sheets are traditional materials that have been used in underground construction for decades. These are typically composed of asphalt or modified bitumen reinforced with polyester or fiberglass.

Modified Bitumen Membranes:

- Atactic polypropylene (APP) or styrene-butadiene-styrene (SBS) modified

- Excellent adhesion to concrete substrates

- Self-healing properties for minor punctures

- Typically torch-applied or self-adhesive

Reinforced Bituminous Sheets:

- Fiberglass or polyester reinforcement for dimensional stability

- Available in various thicknesses (2mm to 5mm)

- Good resistance to hydrostatic pressure

3. Ethylene Propylene Diene Monomer (EPDM) Sheets

EPDM is a synthetic rubber membrane known for its exceptional durability and flexibility.

- Excellent weather and ozone resistance

- Can withstand extreme temperature variations (-40°C to +120°C)

- High elongation properties (up to 600%)

- Resistant to many chemicals and biological growth

- Typically installed with adhesive or mechanical fasteners

4. Spray-Applied Membranes

While not strictly sheet materials, spray-applied membranes are worth mentioning as they provide seamless waterproofing:

- Liquid polyurethane or polymer-modified asphalt

- Forms a continuous, monolithic membrane

- Excellent adhesion to irregular surfaces

- Can be applied quickly over large areas

- Requires skilled application for consistent thickness

Material Selection Criteria

Choosing the appropriate waterproof sheet material for tunnel and underground applications requires careful consideration of several factors:

1. Hydrostatic Pressure Resistance

The membrane must withstand the expected water pressure, which can be significant in deep tunnels or below groundwater tables. Thicker membranes or reinforced materials are typically required for higher pressures.

2. Chemical Resistance

Groundwater often contains various chemicals, including chlorides, sulfates, and carbon dioxide, which can degrade some materials. The membrane must resist these chemicals throughout its service life.

3. Mechanical Properties

The material must have adequate:

- Tensile strength to resist stresses during and after installation

- Puncture resistance to withstand backfilling and construction activities

- Tear resistance to prevent damage propagation

- Flexibility to accommodate structural movements

4. Durability and Service Life

Tunnel waterproofing systems are expected to last the entire design life of the structure, often 100 years or more. The material must resist aging, biological attack, and maintain its properties over time.

5. Installation Considerations

- Ease of handling and installation in confined spaces

- Compatibility with the chosen installation method (welding, adhesion, mechanical fastening)

- Ability to form watertight details at penetrations and transitions

- Tolerance to site conditions (temperature, humidity, substrate condition)

6. Environmental Factors

- Resistance to microbial growth

- Non-toxic composition (especially for potable water tunnels)

- Recyclability or environmental impact at end of life

Installation Methods

Proper installation is crucial for the performance of waterproof sheet materials in tunnel applications. Common installation techniques include:

1. Fully Bonded Systems

The membrane is completely adhered to the substrate using:

- Cold-applied adhesives

- Hot-applied bituminous adhesives

- Self-adhesive membranes with peel-and-stick backing

Advantages:

- Excellent stress distribution

- Minimizes risk of water migration behind the membrane

- Provides secondary structural support

2. Loose-Laid Systems

The membrane is laid over the substrate without full adhesion, often with protection layers:

- Used in conjunction with drainage composites

- Allows for some movement between substrate and membrane

- Typically requires ballast or mechanical fastening at edges

3. Mechanically Fastened Systems

Membranes are secured using:

- Plastic or metal fasteners with sealing plates

- Batten strips at edges and penetrations

- Particularly useful in segmental tunnel construction

4. Welded Systems

Thermoplastic membranes can be joined using:

- Hot air welding

- Extrusion welding

- Solvent welding for certain materials

Creates continuous, homogeneous seams with strength approaching the parent material.

Special Considerations for Tunnel Applications

Tunnel waterproofing presents unique challenges that require special attention:

1. Joint and Detail Waterproofing

- Expansion joints

- Construction joints

- Penetrations (pipes, conduits)

- Transition areas between different materials

- Intersections with other structures

These critical areas often require additional waterproofing measures such as waterstops, sealants, or specialized flashing details.

2. Secondary Protection Layers

Waterproof membranes in tunnels are typically protected by:

- Geotextile protection layers

- Concrete protection slabs

- Drainage composites

- Insulation boards in cold climates

3. Drainage Considerations

An effective tunnel waterproofing system often incorporates drainage behind the waterproof membrane to:

- Relieve hydrostatic pressure

- Channel any leakage to collection points

- Prevent water vapor transmission

4. Quality Control and Testing

Rigorous quality control is essential for tunnel waterproofing:

- Material testing before installation

- Seam testing (peel tests, vacuum tests, spark testing)

- Leak detection systems

- Post-installation inspections

Performance Standards and Testing

Waterproof membranes for tunnels must meet various international standards, including:

- EN 13967 for flexible sheets for waterproofing

- ASTM D7176 for PVC membranes

- ISO 9001 for quality management systems

- Fire resistance standards (e.g., EN 13501-1)

- Chemical resistance testing specific to project requirements

Common tests include:

- Tensile strength and elongation

- Tear resistance

- Puncture resistance

- Peel adhesion

- Water vapor transmission

- Low temperature flexibility

- Accelerated aging tests

Emerging Technologies and Future Trends

The field of tunnel waterproofing continues to evolve with new materials and technologies:

1. Self-Healing Membranes

- Incorporation of microcapsules containing healing agents

- Shape memory polymers that can "close" small punctures

- Bituminous membranes with inherent self-healing properties

2. Smart Waterproofing Systems

- Membranes with embedded sensors to detect leaks

- Conductive layers for moisture monitoring

- RFID tags for quality control and maintenance tracking

3. Sustainable Materials

- Bio-based polymers

- Recycled content membranes

- Reduced VOC emissions during installation

- Easier recyclability at end of life

4. Improved Installation Technologies

- Robotic welding systems for consistent seam quality

- Automated inspection tools

- Advanced computer modeling for detailing complex geometries

Maintenance and Repair

Even with high-quality materials and installation, waterproofing systems may require maintenance:

1. Inspection Techniques

- Visual inspections

- Moisture mapping

- Infrared thermography

- Electrical leak detection

2. Repair Methods

- Injection grouting behind membranes

- Patch repairs with compatible materials

- Sealant application at localized leaks

- Complete membrane replacement in severe cases

Conclusion

Waterproof sheet materials are essential components in the construction of durable, watertight tunnels and underground structures. The selection of appropriate materials requires careful consideration of project-specific requirements, environmental conditions, and long-term performance expectations. With advancements in material science and installation technologies, modern waterproofing systems can provide reliable protection throughout the extended service life of underground infrastructure. Proper design, material selection, installation, and maintenance are all critical to ensuring the effectiveness of the waterproofing system and the longevity of the tunnel structure.

Phone

Phone

Comment

(0)